How to design a pad foundation

For a general introduction, see Pad foundation.

For different types, see Types of pad foundation.

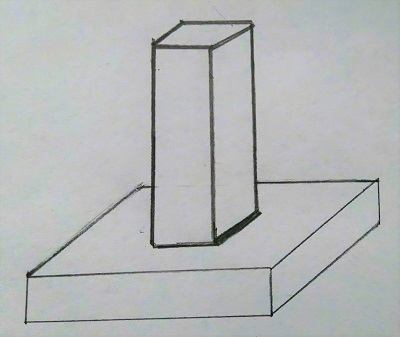

Pad foundations are a form of spread foundation formed by rectangular, square, or sometimes circular concrete ‘pads’ that support localised single-point loads such as structural columns, groups of columns or framed structures. This load is then spread by the pad to the bearing layer of soil or rock below. Pad foundations can also be used to support ground beams.

A pad foundation should be designed to effectively spread a concentrated force into a bearing stratum. They are a popular design solution as they are generally cost-effective and are relatively easy to design and construct, and are suitable for most subsoils except loose sands, loose gravels and filled areas.

In order for pad foundations to spread the load into the soil, the pad must be either sufficiently deep (allowing the force of the load to spread out at a pre-defined angle), or be constructed with adequate reinforcement. The soil’s bearing capacity, as well as the concrete’s strength, are the factors that define the angle of the load’s spread.

The type of skeletal frame will determine the pad foundation design. For example, a cast insitu concrete column will require a kicker and continuity bars to be cast into the pad. Steel frame, timber frame or precast concrete framed structures will require holding-down bolts to be cast into the top of the pad or sockets to be formed.

The following table should be referred to when determining the spread of force within an unreinforced concrete pad.

Depth/projection ratios for unreinforced footings:

Unfactored ground pressure (kN/m²)

a/hf

a = the projection from the face of the column

hf = the depth of the footing

C20/25

C25/30

C30/37

C35/45

≤200

1.2

1.1

1.1

1.0

300

1.5

1.4

1.3

1.2

400

1.7

1.6

1.5

1.4

(Ref. Manual for the design of concrete structures to Eurocode 2.)

For low-rise buildings, it is generally recommended to limit the overall depth of a pad foundation to 1 m from ground level. When designing the pad, care should be taken to ensure that it is large enough to prevent tension within the concrete, which could result in cracking and failure.

Reinforced concrete pads should be designed so that the depth is sufficient to resist a shear force known as ‘punching shear’. This can develop around the perimeter of the column, wall or other vertical component that the pad is supporting. Bending can also occur as the pad footing spreads the load onto the stratum.

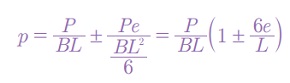

To resist bending moments, the pad footing should be designed so that the force is applied within the middle third of the base. This is known as the ‘middle third rule’ – a design practice that means the size of the foundation is defined according to the resultant force’s centralisation. There is an equation that defines the distribution of compression stress across the pad foundation:

Where:

- p = compressive stress in the soil under the pad foundation.

- P = applied axial load, including the self-weight of the footing.

- B = width of the pad foundation.

- L = length of the pad foundation.

- e = eccentricity of the applied axial load taken at the centre of the bearing.

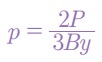

Uplift can occur if the applied force lies outside the middle third of the base. What this means is that where the applied forces are greater than, and acting in the opposite direction to, the self-weight of the pad, it can cause the pad to lift. The equation for calculating the value of the applied bearing stress on the soil is as follows:

- y = distance from the line of action.

- P = nearest edge of the pad footing. This is defined as L/2 - e.

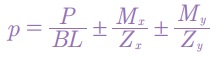

Biaxial bending moments can also be applied to pad foundations. For more information, see Biaxial bending. The equation used to calculate the bearing stress in the soil is as follows:

Where:

- Mx = applied bending moment in the major axis.

- Zx = elastic modulus of the pad foundation in its major axis in plan.

- My = applied bending moment in the minor axis.

- Zy = elastic modulus of the pad foundation in its minor axis in plan.

Depending on the loads, either welded steel fabric or reinforcing bars will be necessary, and arranged in both directions.

It is common to approach the design of the pad as though it were an inverted cantilever supported by the column and carrying the pressure of the soil.

The reinforcement must be designed to be capable of resisting the bending stress, and is similar to that of floor slabs.

[edit] Find out more

[edit] Related articles on Designing Buildings Wiki

- Building foundations.

- Driven piles.

- Footings.

- Groundworks.

- How deep should foundations be?

- Pad foundation.

- Piers.

- Pile foundations.

- Raft foundation.

- Screw pile foundations.

- Strip foundation.

- Trench fill foundation.

- Types of pad foundation.

[edit] External resources

Featured articles and news

Moisture, fire safety and emerging trends in living walls

How wet is your wall?

Current policy explained and newly published consultation by the UK and Welsh Governments.

British architecture 1919–39. Book review.

Conservation of listed prefabs in Moseley.

Energy industry calls for urgent reform.

Heritage staff wellbeing at work survey.

A five minute introduction.

50th Golden anniversary ECA Edmundson apprentice award

Showcasing the very best electrotechnical and engineering services for half a century.

Welsh government consults on HRBs and reg changes

Seeking feedback on a new regulatory regime and a broad range of issues.

CIOB Client Guide (2nd edition) March 2025

Free download covering statutory dutyholder roles under the Building Safety Act and much more.

AI and automation in 3D modelling and spatial design

Can almost half of design development tasks be automated?

Minister quizzed, as responsibility transfers to MHCLG and BSR publishes new building control guidance.

UK environmental regulations reform 2025

Amid wider new approaches to ensure regulators and regulation support growth.

The maintenance challenge of tenements.

BSRIA Statutory Compliance Inspection Checklist

BG80/2025 now significantly updated to include requirements related to important changes in legislation.

Shortlist for the 2025 Roofscape Design Awards

Talent and innovation showcase announcement from the trussed rafter industry.