Pile foundations

|

|

|

|

Contents |

[edit] What are foundations?

Foundations provide support for structures, transferring their load to layers of soil or rock that have sufficient bearing capacity and suitable settlement characteristics. There are a very wide range of foundation types available, suitable for different applications, depending on considerations, such as:

- The nature of the load requiring support.

- Ground conditions.

- The presence of water.

- Durability of the materials.

- Cost.

- Accessibility.

- Sensitivity to noise and vibration.

- Proximity to other structures.

- Load exerted on the piles.

[edit] How are foundations classified?

Very broadly, foundations can be categorised as shallow foundations or deep foundations. Shallow foundations are typically used where the loads imposed by a structure are low relative to the bearing capacity of the surface soils. Deep foundations are necessary where the bearing capacity of the surface soils is insufficient to support loads imposed and so they are transferred to deeper layers with higher bearing capacity.

[edit] What are pile foundations?

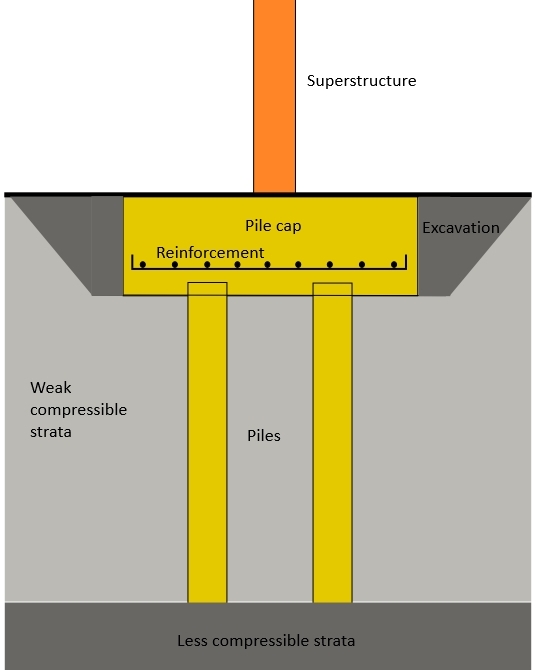

Pile foundations are deep foundations. They are formed by long, slender, columnar elements typically made from steel or reinforced concrete, or sometimes timber. A foundation is described as 'piled' when its depth is more than three times its breadth (ref. Atkinson, 2007).

Pile foundations are principally used to transfer the loads from superstructures, through weak, compressible strata or water onto stronger, more compact, less compressible and stiffer soil or rock at depth, increasing the effective size of a foundation and resisting horizontal loads. They are typically used for large structures, and in situations where soil is not suitable to prevent excessive settlement.

[edit] What are the types of pile foundations?

Piles may be classified by their basic design function (end-bearing, friction or a combination) or by their method of construction (displacement (driven) or replacement (bored)).

[edit] End-bearing piles

End-bearing piles develop most of their friction at the toe of the pile, bearing on a hard layer. The pile transmits load directly to firm strata, and also receives lateral restraint from subsoil.

For more information, see 'end-bearing piles'.

[edit] Friction piles

Friction (or floating) piles develop most of the pile-bearing capacity by shear stresses along the sides of the pile, and are suitable where harder layers are too deep. The pile transmits the load to surrounding soil by friction between the surface of the pile and soil, which in effect lowers the bulb of pressure.

For more information, see 'friction piles'.

[edit] Driven piles

Driven (or displacement) piles are driven, jacked, vibrated or screwed into the ground, displacing the material around the pile shaft outwards and downwards instead of removing it.

Driven piles are useful in offshore applications, are stable in soft squeezing soils and can densify loose soil.

There are two groups of driven piles:

- Driven in situ: Either with a permanent concrete or steel casing, or with temporary casing.

- Preformed: Prefabricated off-site from timber, concrete or steel.

For more information, see 'driven piles'.

[edit] Bored piles

Bored (or replacement) piles remove spoil to form a hole for the pile which is poured in situ. They are used primarily in cohesive subsoils for the formation of friction piles and when forming pile foundations close to existing buildings.

Bored piles are more popular in urban areas as there is minimal vibration, they can be used where headroom is limited, there is no risk of heave, and where it may be necessary to vary their length.

For more information, see 'bored piles'.

If the boring and pouring takes place simultaneously, piles are called continuous flight auger (CFA) piles.

[edit] Other types of piles

[edit] Screw piles

Screw piles have a helix near the pile toe so they can be screwed into the ground. The process and concept is similar to screwing into wood.

For more information, see 'screw pile foundations'.

[edit] Micropiles

Micropiles (or mini piles) are used where access is restricted, for example underpinning structures affected by settlement. They can be driven or screwed into place.

For more information, see 'micropiles'.

[edit] Pile walls

Pile walls can be used to create permanent or temporary retaining walls. They are formed by placing piles directly adjacent to one another. These can be closely-spaced contiguous pile walls or interlocking secant pile walls, which depending on the composition of the secondary intermediate piles can be hard/soft, hard/firm or hard/hard secant walls.

For more information, see 'pile wall', 'sheet piles and 'secant pile wall'.

[edit] Geothermal piles

Geothermal piles combine pile foundations with closed-loop ground-source heat pump systems. They provide support to a structure, as well as acting as a heat source and a heat sink.

In effect, the thermal mass of the ground enables the building to store unwanted heat from cooling systems and allows heat pumps to warm the building in winter. Generally, ground source heat pumps extract heat from the ground by way of underground pipes which are laid either horizontally or vertically in the ground. In geothermal piles, the pipe loops are laid vertically, within the piles themselves.

For more information, see 'geothermal pile foundations'.

[edit] Contiguous piles

Groynes in coastal engineering (CIRIA C793), published by CIRIA in 2020, defines contiguous piles as; ‘…cast-in-place concrete piles immediately adjacent to or touching each other. Sometimes used for plank piles.’

[edit] Others

For more information see: Types of pile foundation.

[edit] What piling equipment is used?

A wide range of equipment is available for piling, including:

- Percussion drivers: hammers driven by steam, compressed air or diesel.

- Hydraulic drivers: hydraulic rams push piles into the ground.

- Vibratory drivers: piles are vibrated into the ground.

- Rotary augers: used to screw replacement piles into the ground.

For more information, see 'piling equipment'.

[edit] Pile caps and beams

Piles can be used individually to support loads or grouped and linked together with a reinforced concrete cap. As it is very difficult to bore or drive piles exactly vertical, the pile cap should be able to accommodate some deviation in the final position of the pile heads. The pile cap should overhang the outer piles, typically by a distance of 100-150 mm on all sides, depending on the size of the pile.

Pile caps can also be linked together with reinforced concrete to create capping beams. At least three capped piles are needed to ensure stability against lateral forces (with the exception of caisson piles). Capping beams are also suitable for distributing the weight of a load-bearing wall, or of close-centred columns to a line of piles. Piles may be staggered in the beam to allow for any eccentricities that may occur in loaded conditions.

The capping beam should be kept clear of the ground where the purpose of the piles is to overcome the problem of the subsoil swell and shrinkage. This can be done by casting the capping beam on polystyrene or other compressive material, thereby allowing an upward ground movement without damage to the beam.

For more information, see 'capping beam'.

[edit] Testing piles

It is advisable to test load at least one pile per scheme by forming a trial pile that is in close proximity but does not form part of the actual foundations. The pile should be overloaded by at least 50% of its working load and held for 24 hours. This provides a check on the ultimate bearing capacity of the pile as well as the workmanship involved in forming the pile.

For more information, see 'testing pile foundations'.

The integrity of new and existing piles can be measured by carrying out a pile integrity test.

[edit] Related articles on Designing Buildings

- Bored piles.

- Building foundations.

- Continuous flight auger piles.

- Driven piles.

- End-bearing piles.

- Friction piles.

- Geothermal pile foundations.

- King pile.

- Knee pile.

- Micropiles.

- Monopile.

- Pad foundation.

- Pile cap.

- Piled raft foundation.

- Pile wall.

- Piling equipment.

- Plank pile.

- Raft foundation.

- Screw pile foundations.

- Secant pile wall.

- Sheet piles.

- Types of pile foundation.

Featured articles and news

Moisture, fire safety and emerging trends in living walls

How wet is your wall?

Current policy explained and newly published consultation by the UK and Welsh Governments.

British architecture 1919–39. Book review.

Conservation of listed prefabs in Moseley.

Energy industry calls for urgent reform.

Heritage staff wellbeing at work survey.

A five minute introduction.

50th Golden anniversary ECA Edmundson apprentice award

Showcasing the very best electrotechnical and engineering services for half a century.

Welsh government consults on HRBs and reg changes

Seeking feedback on a new regulatory regime and a broad range of issues.

CIOB Client Guide (2nd edition) March 2025

Free download covering statutory dutyholder roles under the Building Safety Act and much more.

AI and automation in 3D modelling and spatial design

Can almost half of design development tasks be automated?

Minister quizzed, as responsibility transfers to MHCLG and BSR publishes new building control guidance.

UK environmental regulations reform 2025

Amid wider new approaches to ensure regulators and regulation support growth.

The maintenance challenge of tenements.

BSRIA Statutory Compliance Inspection Checklist

BG80/2025 now significantly updated to include requirements related to important changes in legislation.

Shortlist for the 2025 Roofscape Design Awards

Talent and innovation showcase announcement from the trussed rafter industry.

Comments

[edit] To make a comment about this article, click 'Add a comment' above. Separate your comments from any existing comments by inserting a horizontal line.