Rethinking the design and specification of ground floors

[edit] Introduction

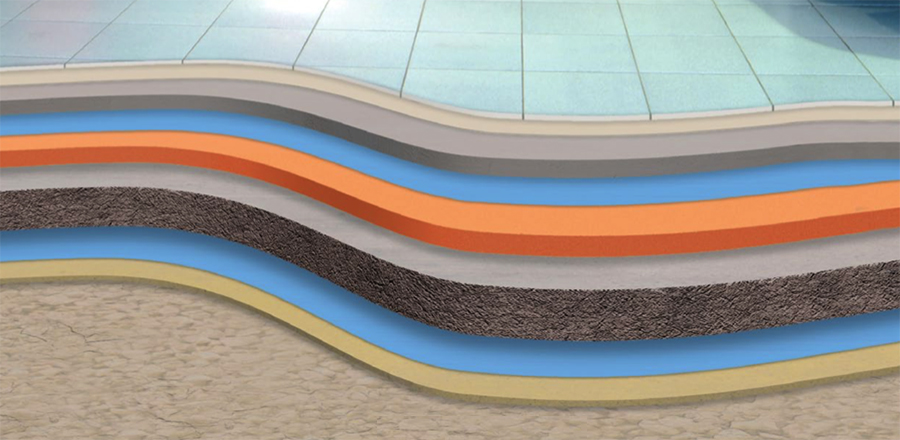

The ground floor of most buildings might seem like a relatively simple part of the building fabric to design and specify: an appropriate supporting structure for the ground conditions; thermal insulation to meet the required U-value; a protective floor covering and, if required, a floor finish.

Creating a built environment that is more flexible and adaptable is going to be a crucial part of our net zero future. Somehow, we must balance the increasing demand for new construction against finite resources and the essential need to reduce greenhouse gas emissions.

Provide a couple of membrane layers in the right place within that build-up and you should have a perfectly functional floor. Except, it is surprising how often that does not turn out to be the case. Common technical enquiries where something has gone awry with the floor include the following examples:

One type of insulation has been specified, but the structural engineer has identified that a better compressive strength is required. The specifier or contractor does not think they can now meet the required U-value while also providing the necessary load bearing performance.

A contractor is unsure whether they can install the thermal insulation above or below the damp proof membrane (DPM). Or, worse, they have installed it incorrectly but want reassurance that the floor will still perform as needed.

Issues such as these increase the likelihood of performance gaps occurring. The in-service performance of the floor – be that thermal, load bearing or moisture resistance performance – does not match what was intended at design stage.

If there is a struggle to make floors perform as intended in the first instance, then that has implications for addressing one of the most pressing issues currently facing the construction industry: how do we make buildings more adaptable for the future?

[edit] Why is adaptable design important – and why is it not current practice?

Creating a built environment that is more flexible and adaptable is going to be a crucial part of our net zero future. Somehow, we must balance the increasing demand for new construction against finite resources and the essential need to reduce greenhouse gas emissions.

Prolonging the useful life of buildings, minimising demolition, and extending the life of components across multiple projects is going to be part of that balance. Specifying floor constructions that can serve a range of building uses could do just that. The floor could be left unaltered, even if other elements of the building fabric above do have to be changed.

At the moment, it is often easier to demolish a building and start again than to try and work with the existing fabric. But that is not compatible with climate and biodiversity emergencies.

Existing buildings have a lot of embodied carbon tied up in them. Demolition sees the carbon already emitted effectively wasted, while more emissions are incurred through the new construction. Demand for new buildings also puts pressure on finite reserves of raw materials, rather than looking at how the resources we have already extracted can be used more efficiently.

Another issue with current floor build-ups is that traditional design and construction processes mean most buildings are essentially prototypes. The materials and installation techniques might be similar across different projects, but repetition and total consistency is not possible. As a result, even two ‘identical’ buildings will be put together in a slightly different way and perform differently in use. Extending a building is relatively simple so, in that sense, buildings are adaptable – but only if they need to be made bigger to suit growth or expansion.

What if a building ever needs to be made smaller?

A key issue with ‘familiar’ construction materials and techniques is that they can be put together on site but taking them apart again is almost impossible – or, at least, undesirable. It might be technically feasible but is rarely economically feasible.

[edit] What might ground floor build-ups look like in adaptable buildings?

There are exciting developments being trialled across the construction industry that aim to overcome some of the challenges and risks in traditional construction.

Design for manufacture and assembly (DfMA), and construction platforms, represent solutions that are likely to form the future of our built environment. Floors are likely to be constructed from panels or ‘cassettes’ that are compatible with, and easily fixed to, the primary structural frame. This will remove the need for wet processes on site, like mixing and pouring concrete slabs and screeds.

Until such time as those solutions become the norm, however, how can traditional ground floor constructions be specified with greater adaptability in mind?

A traditional floor cannot be ‘assembled’ or ‘disassembled’ so that its area changes to match a larger or smaller building. However, it is possible to ensure that it is capable of bearing a wider range of loads, and so be capable of serving different building uses.

One way to look at it is to consider how a ground floor could be specified to ensure that it can be used as much as possible – including effectively being reused if the occupation of the building substantially changes.

[edit] How can the floor constructions described in BS 5250 help?

BS 5250:2021 Management of moisture in buildings is the ideal starting point for thinking about the best floor construction options for the long term. The code of practice looks at buildings holistically with regards to moisture, which is vital when aiming to achieve building fabric with an extended useful life. Its recommendations for floors cover the following four categories of construction.

[edit] 1. Groundbearing floors with DPM

This type of floor typically consists of a concrete slab that is cast onto, and supported by, a prepared base – usually sand-blinded hardcore. The DPM acts as a barrier to moisture from the ground.

The DPM should be positioned in the floor build-up based on the thermal insulation material used. Many thermal insulation materials are affected by moisture and therefore have to be installed above the DPM, in order to ensure that they deliver their intended performance.

The combination of insulation and DPM can be positioned above or below the concrete slab. Figures 3 and 4 of BS 5250:2021 clearly illustrate all of the ways in which this type of floor can be built up. The decision about where to place the insulation layer relative to the concrete slab depends on the intended heating regime of the building.

[edit] 2. Ground bearing floors without DPM

In modern construction, with the possible exception

of some historic buildings, a new floor should not be constructed without a DPM. This type of floor is therefore generally only found in existing buildings, is very unlikely to have any thermal insulation, and is outside the scope of this article.

[edit] 3. Suspended floors

Suspended floors separating a conditioned space from an unconditioned void or space should feature thermal insulation.

At ground level, most new suspended floors are a concrete deck (such as a block and beam system, or a pre-cast slab), with timber joist floors being found in older properties. The requirement for a DPM depends on the design of the floor and the ground conditions. The thermal insulation is not in direct contact with the ground.

‘Suspended floors’ also deals with intermediate floors, including those over unconditioned spaces, which is again outside of the scope of this article.

[edit] 4. Basement floors

The detailing of basement floors (and walls) depends on the ground conditions on site, whether the basement is new or existing, how the basement will be waterproofed, and the intended use of the basement (including moisture generation inside the room(s)).

Like ground bearing floors with a DPM, if the thermal insulation is to the outside of the basement structure and in contact with the ground, then it needs to be capable of retaining its thermal performance even when exposed to moisture.

[edit] Specifying insulation for ‘adaptable’ ground floors

In ground bearing floors with a DPM and suspended ground floors (and basement floors where appropriate), the specification of appropriate insulation can deliver long-term thermal, load bearing and moisture resistance performance.

Extruded polystyrene (XPS) offers an ideal balance of thermal performance, compressive strength, robustness and moisture protection. Its load bearing capabilities mean it is commonly specified in residential, commercial and industrial buildings alike.

XPS requires only a minimal increase in thickness to achieve the same U-value as other lightweight foam boards, which offer slightly better thermal conductivities but less load bearing capability – and therefore less flexibility in the types of floors they can be specified in.

Another advantage of XPS is its moisture resistance, meaning it can be installed directly on the ground with the DPM over it. The floor slab and floor finish can then be specified to suit a range of potential future uses.

Conveniently, the insulation will never need to be disturbed, regardless of any work carried out to renew the internal floor finish. It will therefore continue to deliver the intended U-value and the required load bearing, protected by the floor slab regardless of construction work carried out above. It can therefore deliver a floor capable of serving not just one use, but multiple uses for the same building.

Polyfoam XPS’s Floorboard range is suitable for different types of ground floor construction. Find out more, and view our online CPD, at polyfoamxps.co.uk

This article appears in the AT Journal Spring Issue No 145 as "Is it time to rethink the design and specification of ground floors?", written by Rob Firman, Technical and Specification Manager, Polyfoam XPS.

--CIAT

[edit] Related articles on Designing Buildings

- Ash or oak wood flooring.

- Bamboo flooring.

- Carpet.

- Click and lock flooring.

- Cork flooring.

- Cosmati work.

- Floor insulation.

- Glass block flooring.

- Laminate flooring.

- Mastic asphalt flooring.

- Natural stone flooring.

- Polymeric flooring.

- Polystyrene.

- Resilient flooring.

- Resin flooring.

- Rubber flooring.

- Terrazzo.

- Thermal insulation for buildings.

- Types of flooring.

- Vinyl flooring.

Featured articles and news

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

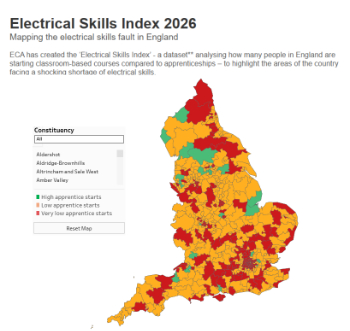

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description fron the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

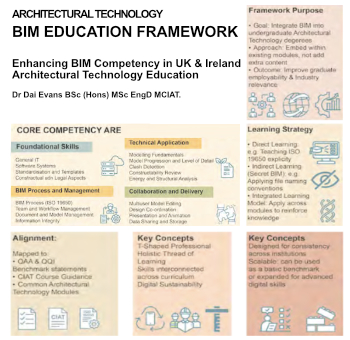

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”

Guidance notes to prepare for April ERA changes

From the Electrical Contractors' Association Employee Relations team.

Significant changes to be seen from the new ERA in 2026 and 2027, starting on 6 April 2026.

First aid in the modern workplace with St John Ambulance.

Solar panels, pitched roofs and risk of fire spread

60% increase in solar panel fires prompts tests and installation warnings.

Modernising heat networks with Heat interface unit

Why HIUs hold the key to efficiency upgrades.