Quality checklist

Contents |

[edit] Background

The toolkit of Quality Management professional typically includes various tools and techniques to help in the process of quality planning (setting out requirements), quality control (ensuring requirements will be met, and quality improvement (assessing and improving the effectiveness of the quality plan). One of the most basic and common quality planning and control tools is the checklist. At its most basic, a checklist is simply a list of items to be carried out to complete a task and to demonstrate that these were completed as planned.

A checklist is not to be confused with a “check sheet” (Figure 1), which is a quality improvement tool used to maintain a tally of events or defects, or to generate data for statistical control charting a process. Professor Kaoru Ishikawa included check sheets in his list of the elementary tools of quality control (Ishikawa K, 1985 – What is Total Quality Control, p198). According to Ishikawa, as much as ninety-five percent of problems within a company could be solved using the seven basic tools.

| Figure 1 – example of a check sheet which is used to generate simple statistical analysis of product characteristics or defects |

This article focusses on checklists. Checklists are used in many industries, notably in manufacturing and engineering, to provide evidence that essential manufacturing or maintenance tasks have been completed in accordance with an approved plan. For this reason, they are often used in safety-critical systems which require multiple simple and repetitive tasks to prevent faults with potentially severe consequences. A typical example is in the routine operation and maintenance of aircraft systems. Even though airline personnel are highly trained and experienced, the potentially disastrous consequences of missing out even simple tasks mandates that each flight is preceded by running through checklists to ensure all steps are carefully planned, completed and controlled.

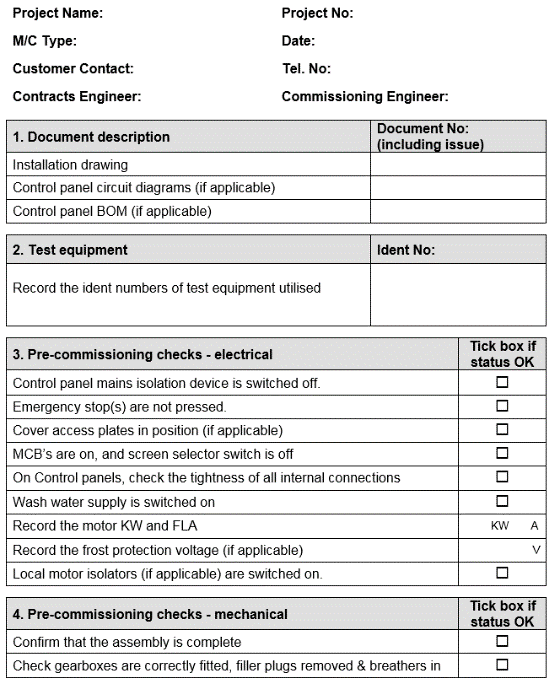

| Figure 2 – example checklist for controlling standardised tasks |

Similarly, in construction, checklists may be used on their own or in conjunction with other tools, such as Inspection and Test Plans, to show that essential construction or management tasks have been carried out or addressed.

In construction, checklists are commonly used to manage safety. For example, they may be used to record that essential daily, weekly or task-specific safety checks have been carried out, as may be used in a typical Permit to Work. When managing others, checklists can remind supervisors to ensure sub-contractors are fully briefed, standard procedures are in place, tools and materials are checked for adequacy, and appropriate personal protective equipment is in use. In this way the checklist can be used both for planning an activity and coaching supervisors in standardised procedures.

[edit] Purpose

The main purpose of checklists is to provide quality assurance and control. They achieve this by:

- Providing a standardised list of the essential items that must be completed or a standard method for recording essential production or inspection data.

- Allowing other relevant data to be collected when used: date, project references, location, details of people or companies involved in the activity, quantitative or qualitative data directly connected with the activity (e.g. concrete cube test data, duration of the activity, etc.)

- Recording failures and subsequent actions, which can be used for simple analysis and to prevent defects from passing forward to subsequent stages and, ultimately, the customer.

- Using signatures, stamps or similar methods to provide evidence and assurance of independent or appropriate inspections or approvals. This requirement can often support an organisation to show it has met regulatory, contract or legal requirements

- Integrating checklists into an organisation’s management systems facilitates training in standard procedures, to evaluate process performance and improve it over time.

[edit] Essential characteristics:

Checklists share many of the characteristics of other common quality tools. For example, a typical Inspection and Test Plan (ITP) also details a list of tasks to be completed as well as recording acceptance or approval. As in the case of ITPs, an important element of a checklist is that its design and use is approved and evidenced using signatures or suitable electronic equivalents.

The design of a checklist should be approved by a competent party, to ensure it covers the most important requirements in sufficient detail and includes intermediate hold-points at critical stages. This is particularly important for safety-critical items – e.g. ensuring bolts are tightened to the correct torque – or where subsequent activities will make later inspection or detection of any defects difficult or impossible – e.g. backfilling buried services, pouring reinforced concrete or similar. When in use, sign-off of checklist should be by someone independent of the task being carried e.g. Principal Contractor sign-off of subcontractor’s checklist.

What separates a checklist from ITPs and other similar tools is its simplicity and ease of use. This simplicity makes checklists ideal tools to be used by operatives and managers directly at the place of work, including out on a live construction site. Checklists can be completed with relative ease and without interrupting train of thought or the execution of the task at hand. A simple design also means that checklists can be easily developed in digital forms to be filled in on mobile tablets, smartphones or similar devices.

The content and structure of any checklist must be suitable for managing quality-related risks. As in any field of quality management, it is important that any checklist is developed so that it is relevant to the needs of its customer and stakeholders: safety, quality, cost etc. It must also be regularly updated so that it remains relevant.

[edit] Points to consider

It is important that workers who take time to use checklists are involved in their development and receive regular management training and feedback, so that they appreciate the value of the data and their efforts in collecting it. Failure to do so is likely to result in a “tick box” mentality, poor quality data and increased quality risks to the organisation. It is also vitally important that they are completed at the time and place of the inspection or test and not left until “back in the office”.

The correct use of checklists in quality control is well illustrated by the example of inspection failures at the MOX Demonstration Facility (MDF) at Sellafield (HSE, 2000). In 2000 investigations by British Nuclear Fuel Limited (BNFL) and the HSE’s Nuclear Inspectorate discovered that some records of nuclear pellet physical property checks had been falsified by process workers. This involved workers substituting manual sample check records of pellet physical characteristics, as required by a stringent customer specification, with data copied from other inspections. Although the investigation concluded that there were no resulting significant safety risks, discovery of the incident raised serious questions over MDFs supervision and safety culture, as well as causing considerable damage to BNFL’s reputation. The HSE found that significant causal factors included inadequate management control and supervision of operations, deficiencies in training and overall safety culture, and the tedious nature and poor design of the manual inspection process.

[edit] References

- Ishikawa K, 1985, What is Total Quality Control? P198.

- Health and Safety Executive, “Health and safety leadership checklist”, https://www.hse.gov.uk/leadership/checklist.htm

- HSE (2000) An investigation into the falsification of pellet diameter data in the MOX demonstration facility at the BNFL Sellafield site and the effect of this on the safety of MOX fuel in use. HSE February 2000. HSE Nuclear Safety Division Information Centre R004, St Peter’s House, Balliol Road, Bootle, Merseyside L20 3LZ.

- Wikipedia, “Checklist”, https://en.wikipedia.org/wiki/Checklist

Rev 1.0 (15/8/2020): Original article written by Luca Fiderio & reviewed by Keith Hamlyn on behalf of the Construction Special Interest (ConSIG) Comptency Working Group (CWG). Article peer reviewed by the CWG and accepted for publication by the ConSIG Steering Committee.

--ConSIG CWG 16:06, 17 Aug 2020 (BST)

[edit] Related articles on Designing Buildings Wiki

- Change control: a quality perspective.

- Checking and Approval in Design – A Quality Management Perspective.

- Collaboration: a quality management perspective.

- Design freeze: a quality perspective.

- Design: a quality management perspective.

- Digital quality management in construction.

- Quality culture and behaviours.

- Quality management systems (QMS) - beyond the documentation.

- Quality manuals and quality plans.

- Quality tools: fishbone diagram.

- Stakeholder management: a quality perspective.

- Quality.

Featured articles and news

Retrofit 25 – What's Stopping Us?

Exhibition Opens at The Building Centre.

Types of work to existing buildings

A simple circular economy wiki breakdown with further links.

A threat to the creativity that makes London special.

How can digital twins boost profitability within construction?

The smart construction dashboard, as-built data and site changes forming an accurate digital twin.

Unlocking surplus public defence land and more to speed up the delivery of housing.

The Planning and Infrastructure Bill

An outline of the bill with a mix of reactions on potential impacts from IHBC, CIEEM, CIC, ACE and EIC.

Farnborough College Unveils its Half-house for Sustainable Construction Training.

Spring Statement 2025 with reactions from industry

Confirming previously announced funding, and welfare changes amid adjusted growth forecast.

Scottish Government responds to Grenfell report

As fund for unsafe cladding assessments is launched.

CLC and BSR process map for HRB approvals

One of the initial outputs of their weekly BSR meetings.

Architects Academy at an insulation manufacturing facility

Programme of technical engagement for aspiring designers.

Building Safety Levy technical consultation response

Details of the planned levy now due in 2026.

Great British Energy install solar on school and NHS sites

200 schools and 200 NHS sites to get solar systems, as first project of the newly formed government initiative.

600 million for 60,000 more skilled construction workers

Announced by Treasury ahead of the Spring Statement.

The restoration of the novelist’s birthplace in Eastwood.

Life Critical Fire Safety External Wall System LCFS EWS

Breaking down what is meant by this now often used term.

PAC report on the Remediation of Dangerous Cladding

Recommendations on workforce, transparency, support, insurance, funding, fraud and mismanagement.

New towns, expanded settlements and housing delivery

Modular inquiry asks if new towns and expanded settlements are an effective means of delivering housing.

Comments

This is so useful article.