Virtual reality and manufacturing

Contents |

Introduction

Through the use of a headset, users are able to experience a constructed world that doesn’t exist in reality. This computer-generated 3D imagery provides an immersive experience that gives the appearance of a 3D life-like environment.

Unlike reality, this computer-generated imagery has no limits. Virtual reality technology has been present for the past decades, with simulation, integration, and digital design being applied to streamline the manufacturing process.

Increased efficiency

Virtual reality is a technology capable of greatly increasing overall efficiency, including the end product and all associated manufacturing processes. Similar to rapid prototyping, virtual reality aids in the design process as it helps to provide insight into potential design flaws.

Ford has utilised the Oculus Rift headsets in order to improve and develop their automotive designs. Through the simulation of weather conditions and different types of roads from the driver’s perspective, the company was able to achieve an optimised design.

The company’s Immersion Lab permits Ford’s employees to walk around a car, sit in it, and observe every component of its construction. Approximately 30 to 40 employees can experience this simulation, as it’s displayed on a high-resolution wall.

Examining the interior and exterior of their vehicles in such a way allows Ford to observe light positioning and its shape and size, before the building process. In 2013 alone, the company observed more than 135,000 individual details on 193 virtual prototypes.

Visualisation

Throughout the manufacturing process, virtual reality enables the visualisation of every design is immersive and detailed ways. The 3D rendering allows for the construction of prototypes on a large scale, without requiring the expense of building it.

Virtual reality reduces production costs through the identification of material weak spots since the first steps in the design process. Making changes in the beginning stages ensures simpler and less expensive processes down the line.

This technology creates walk-through designs, which improves training practices for apprentices. Learning through simulations recreates real-life scenarios without the potential hazards of a mistake, before the physical work starts.

Collaboration

Collaboration in engineering is a vital process in order to streamline designs and manufacturing processes. Through the wide range of techniques from various sources, companies manage the quality of their products and guarantee increased innovation and smooth operations.

3D product models allow for sharing and work to be carried out by several sources, similarly to a virtual reality game. As virtual reality surroundings are close to reality, distance between engineers doesn’t affect projects.

With the increased connectivity through the Internet of Things and the Industry 4.0, all internet-connected devices improve the communication efficacy of engineers. Virtual reality is becoming more affordable by the day, which will result in the expansion of the adoption of the technology.

As modern companies already utilise this technology, its proven success showcases how virtual reality is used to create better products for consumers. The future of this technology will see even bigger improvements on how the manufacturing process can benefit from a streamlined design process and a decrease in design flaws.

--European Springs and Pressings Ltd 12:24, 23 Feb 2017 (BST)

Related articles on Designing Buildings Wiki

- Advanced construction technology.

- Artificial intelligence and civil engineering.

- Artificial intelligence and surveying.

- Augmented reality in construction.

- Cobots.

- Computer-generated imagery (CGI).

- Construction innovation.

- Gravity Sketch.

- Immersive Hybrid Reality iHR.

- Mixed reality.

- Photographing buildings.

- Robots.

- TruVision.

- Virtual construction model.

- Virtual reality and big data disrupting digital construction.

- Virtual reality in construction.

Featured articles and news

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.

Cutting carbon, cost and risk in estate management

Lessons from Cardiff Met’s “Halve the Half” initiative.

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

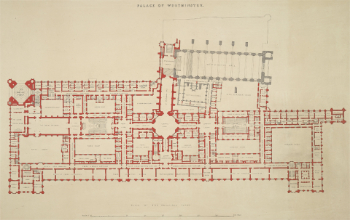

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.