Tensile strength

|

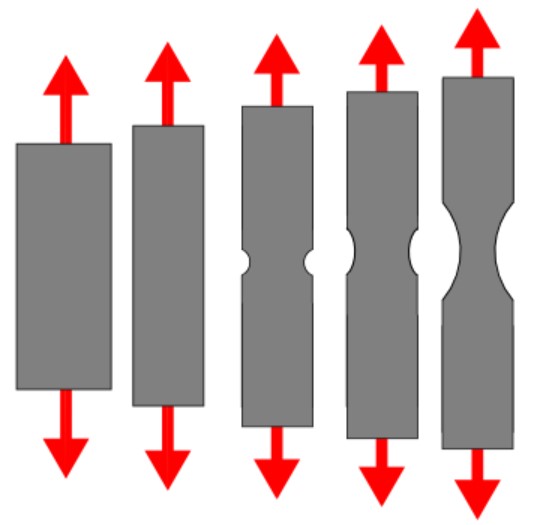

This schematic depiction illustrates how, prior to necking, the entire material evenly undergoes plastic deformation. Once an unstable neck forms, the cross-sectional area of the neck will continue to decrease under load, while the un-necked material no longer plastically deforms. |

Contents |

[edit] Introduction

Tensile strength can be defined as the force required to pull a material in opposite directions to the point of permanent deformation or failure. Tensile strength is the resistance to tension. It is the opposite of compression strength, which is the resistance of compression when items are pushed together.

As an engineering characteristic, tensile strength is significant in materials used for construction. It gauges the suitability of building materials for various applications, particularly those materials that will be required as structural elements. When describing the properties of materials such as metals and alloys, the tensile strength may be included in material specification documents.

[edit] Stress, tension and tensile strength

Tension is a state of stress in which a material is being pulled apart, for example a cable that is attached to a ceiling with a weight fixed to its lower end. Under the influence of gravity, the weight exerts a downward pressure that produces tension in the cable, as does the reaction at the fixing point in the ceiling.

Tension has different effects on materials: concrete does not accommodate tensile stresses well and may crack and suffer extensive damage – with little elongation; while steel is very strong in tension and can elongate substantially under load. It is for this reason that concrete is often reinforced with steel rebar.

The amount of tensile stress a material can tolerate before being pulled apart is defined as its tensile strength. When the stress of certain types of material reaches tensile strength, it will distort to form an area referred to as a neck. This constricted region is typically where the material will fracture. This occurrence is sometimes referred to as the necking phenomenon.

[edit] Three types of tensile strength

Engineering properties associated with materials can be measured according to three different types of tensile strength. These include:

- Yield strength. This refers to the approximate amount of stress a material can undergo prior to experiencing permanent deformation of 0.2% of its original shape.

- Ultimate strength. Ultimate tensile strength (UTS) is measured in units of force per cross-sectional area. It refers to the maximum stress a material can undergo prior to experiencing failure to the point it will be unable to return to its original shape. UTS is an intensive property - it is a characteristic of the material that will be consistent regardless of the sample size. (Note that tensile strength and ultimate tensile strength are not completely synonymous, although they are sometimes used interchangeably. UTS is a specific type of tensile strength.)

- Fracture or breaking strength. This type of tensile strength is the point (or stress value) during a tensile strength test where rupture to the material occurs.

This chart shows the ultimate tensile strength of some typical materials (depending on the manufacturing process and purity or composition of the materials).

| Material | Ultimate tensile strength (MPa) |

| Silicon | 7000 |

| Basalt fibre | 4840 |

| Boron | 3100 |

| Diamond | 2800 |

| Sapphire | 1900 |

| Tungsten | 1510 |

| Brass | 500 |

| Structural steel | 400 to 500 |

| Bamboo | 350 to 500 |

| Copper | 220 |

| Human hair | 200 to 250 |

| Wood (pine, taken parallel to the grain) | 40 |

| Rubber | 16 |

| Marble | 13 |

| Concrete | 2 to 5 |

[edit] Testing tensile strength

It is possible to measure the tensile strength of materials precisely by conducting an elongation test under carefully controlled conditions. This tensile test (also known as a tension test) uses a universal testing machine (UTM) to stretch the specimen at slow, continuous, standardised rate until it fails.

UTMs can typically have testing capacities of up to 53 Mega Newtons (MN) which is equal to a 5,404 tonne force.

[edit] Related articles on Designing Buildings

- Compression.

- Compressive strength.

- Structural stress.

- Tensegrity.

- Tensegrity bamboo pavilion

- Tensile structures.

- Tension.

- The development of structural membranes.

- Ties.

[edit] External resources

Featured articles and news

ECA progress on Welsh Recharging Electrical Skills Charter

Working hard to make progress on the ‘asks’ of the Recharging Electrical Skills Charter at the Senedd in Wales.

A brief history from 1890s to 2020s.

CIOB and CORBON combine forces

To elevate professional standards in Nigeria’s construction industry.

Amendment to the GB Energy Bill welcomed by ECA

Move prevents nationally-owned energy company from investing in solar panels produced by modern slavery.

Gregor Harvie argues that AI is state-sanctioned theft of IP.

Heat pumps, vehicle chargers and heating appliances must be sold with smart functionality.

Experimental AI housing target help for councils

Experimental AI could help councils meet housing targets by digitising records.

New-style degrees set for reformed ARB accreditation

Following the ARB Tomorrow's Architects competency outcomes for Architects.

BSRIA Occupant Wellbeing survey BOW

Occupant satisfaction and wellbeing tool inc. physical environment, indoor facilities, functionality and accessibility.

Preserving, waterproofing and decorating buildings.

Many resources for visitors aswell as new features for members.

Using technology to empower communities

The Community data platform; capturing the DNA of a place and fostering participation, for better design.

Heat pump and wind turbine sound calculations for PDRs

MCS publish updated sound calculation standards for permitted development installations.

Homes England creates largest housing-led site in the North

Successful, 34 hectare land acquisition with the residential allocation now completed.

Scottish apprenticeship training proposals

General support although better accountability and transparency is sought.

The history of building regulations

A story of belated action in response to crisis.

Moisture, fire safety and emerging trends in living walls

How wet is your wall?

Current policy explained and newly published consultation by the UK and Welsh Governments.

British architecture 1919–39. Book review.

Conservation of listed prefabs in Moseley.

Energy industry calls for urgent reform.