Pelletisation of rice husks for energy use

[edit] From Field to Gas: The Trip of Rice Husks through Pelletisation

In the quest of lasting power options, the trip of rice husks from field to fuel takes spotlight. Via the process of pelletisation though a rice bran pellet machine, these apparently trivial farming by-products are transformed right into energy-rich pellets that hold the promise of cleaner and also a lot more effective power generation. Let's embark on the interesting trip of rice husks as they shift from fields to coming to be a valuable source of gas.

[edit] 1. Gathering Rice and Gathering Husks

The journey starts in the rice paddies, where rice is harvested for consumption. After the rice grains are collected, the outer layer, referred to as the husk or hull, remains as a deposit. Commonly thought about waste, these husks hold untapped capacity for power manufacturing as well as ecological conservation.

[edit] 2. Cleaning up as well as Preparation

The gathered husks undergo a meticulous cleansing procedure to eliminate contaminations such as dust, dirt, and also recurring rice grains. Cleaning up the husks is crucial for making sure the quality of the final pellets and the performance of the pelletisation process.

[edit] 3. Drying out the Husks

Adhering to cleansing, the husks are dried to decrease their wetness web content. Reduced dampness levels are essential for reliable pelletisation, as excess dampness can impede the binding procedure as well as cause suboptimal pellet top quality. Correct drying makes certain that the husks await the following phases of transformation.

[edit] 4. Grinding and also Size Reduction

When dried, the husks are ground right into smaller fragments, producing a carefully textured material. This action is necessary for attaining harmony in the pellet structure and size, which subsequently affects the combustion performance as well as energy result of the last pellets.

[edit] 5. Pelletisation Process

The heart of the trip lies within the pelletisation process itself. The prepared rice husk fragments are fed right into a pelletisation machine, which includes rollers as well as a die. Right here, the bits go through compression, warm, as well as stress to create cohesive as well as energy-dense pellets.

- Compression and also Heat - As the rice husk fragments pass through the pelletisation machine, the stress put in by the rollers presses the particles together. The heat generated during this procedure softens the all-natural lignin within the husks, which serves as a binding representative.

- Die design as well as Shaping - The die and roller design plays a pivotal duty in shaping the pellets. Different dies can be used to produce pellets of differing sizes and shapes, accommodating different energy applications. The pellets are formed as the compressed husk particles go through the die.

[edit] 6. Air conditioning and Collection

When the pellets are formed, they are launched from the pelletisation machine as well as call for air conditioning. Air conditioning avoids the pellets from breaking because of their high temperature. Air conditioning systems help strengthen the pellets' structure, guaranteeing their integrity throughout storage and transportation.

[edit] 7. Quality Control

Quality assurance is a vital action to make certain that the generated pellets satisfy the desired criteria. The pellets are evaluated for size, density, durability, and total quality. Any substandard pellets are gotten rid of from the batch, ensuring that only top notch pellets are dispersed.

[edit] 8. Storage as well as Distribution

After quality control, the rice husk pellets await storage space and also distribution. These small and also energy-dense pellets can be utilised for different applications, such as home heating, power generation, and also commercial procedures.

[edit] 9. Adding To Renewable Energy

The journey of rice husks from field to fuel adds to the development of renewable resource sources. By making use of a farming by product that was as soon as thrown out, we decrease waste, lower carbon emissions, and change in the direction of a much more sustainable energy mix.

[edit] 10. Environmental and also Economic Impact

The trip of rice husks via pelletisation has both environmental and also economic ramifications. It minimises the stress on land fills, decreases air pollution from burning, as well as supplies financial chances for farmers as well as pellet suppliers.

[edit] Conclusion

To conclude, the journey of rice husks from field to fuel displays the power of development consequently farming deposits right into useful energy sources. With thorough steps of prep work, pelletisation, as well as quality control, rice husks go through a transformative process that straightens with our quest for cleaner and extra sustainable power solutions. This journey, from fields to sustain, stands as a testament to human ingenuity and the capacity for positive adjustment in power generation and also environmental preservation.

[edit] Related articles on Designing Buildings

Featured articles and news

CIOB student competitive construction challenge Ireland

Inspiring a new wave of Irish construction professionals.

Challenges of the net zero transition in Scotland

Skills shortage and ageing workforce hampering Scottish transition to net zero.

Private rental sector, living standards and fuel poverty

Report from the NRH in partnership with Impact on Urban Health.

.Cold chain condensing units market update

Tracking the evolution of commercial refrigeration unit markets.

Attending a conservation training course, personal account

The benefits of further learning for professsionals.

Restoring Alexander Pope's grotto

The only surviving part of his villa in Twickenham.

International Women's Day 8 March, 2025

Accelerating Action for For ALL Women and Girls: Rights. Equality. Empowerment.

Lack of construction careers advice threatens housing targets

CIOB warning on Government plans to accelerate housebuilding and development.

Shelter from the storm in Ukraine

Ukraine’s architects paving the path to recovery.

BSRIA market intelligence division key appointment

Lisa Wiltshire to lead rapidly growing Market Intelligence division.

A blueprint for construction’s sustainability efforts

Practical steps to achieve the United Nations Sustainable Development Goals.

Timber in Construction Roadmap

Ambitious plans from the Government to increase the use of timber in construction.

ECA digital series unveils road to net-zero.

Retrofit and Decarbonisation framework N9 launched

Aligned with LHCPG social value strategy and the Gold Standard.

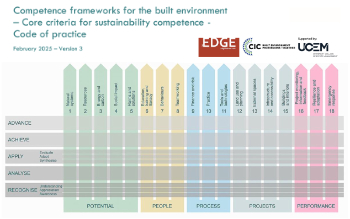

Competence framework for sustainability

In the built environment launched by CIC and the Edge.

Institute of Roofing members welcomed into CIOB

IoR members transition to CIOB membership based on individual expertise and qualifications.

Join the Building Safety Linkedin group to stay up-to-date and join the debate.

Government responds to the final Grenfell Inquiry report

A with a brief summary with reactions to their response.