Dowel laminated timber DLT

Dowel Laminated Timber (DLT) is also know as brettstapel, literally meaning board stack in German. it is a technique of constructing large-scale solid timber panels for use as structural or non-structural elements, utilising smaller untreated sawn timber sections, which are mechanically fixed together with timber dowels.

In a similar way to traditional green oak frame the dowels are seasoned or dried, whilst the main body of timbers are not, so the have a higher moisture content, the dowels soak the moisture from their wetter surroundings and expand ensuring the dowels connection is strong and tight. In oak framing structure the dowels tend to also be made from oak, in DLT they may be made from beech or any other suitably dried hardwood, in both cases the structure and dowels dry over time creating stable established connections.

DLT is said to have been originally conceived by the German engineer Julius Natterer in around the 1970s (hence the reason it is still often referred to as brettstaple). At this time the technique consisted of low grade posts of sawn timber laid side by side, continuously nailed together to create solid structural elements, which then evolved to include glues for increased strength and wider spans. Apart from issues around end of life scenarios, the randomly placed nails also caused problems for modifying or cutting any elements.

In 1999 a German company developed a dowelled wood system (Dübelholz) replacing the nails, this overcame the issues of modification and end-of life because the system became a single material solution. However contraction and expansion from variations in temperature or moisture over time, could potentially cause separation along the dowel axi, compromising strength leading to reintroduction of glue or nails.

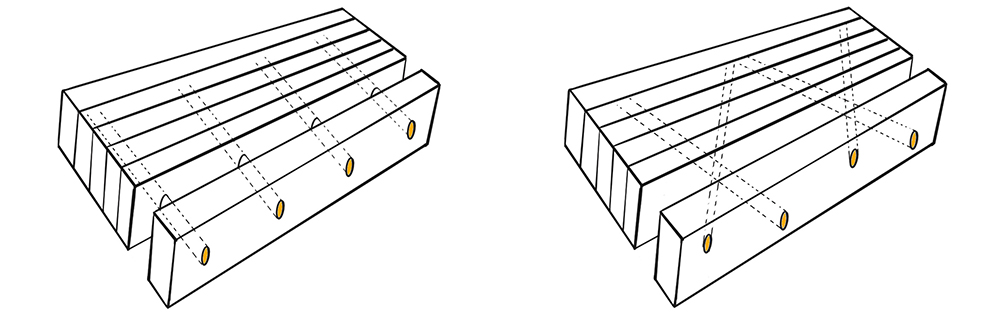

2001 An Austrian company developed a system of inserting timber dowels at angles through the posts in ‘V’ and ‘W’ formations to solve the issue, it virtually eliminated the potential for movement gaps retaining a 100% timber product. Other manufacturers have different means of dealing with the issue, including driving dowels through rotating layers of boards, though this is perhaps the most innovative.

Today many different companies manufacture Brettstapel in Austria, Germany, Switzerland and Norway. The most common form of Brettstapel is the perpendicular dowel with the majority of systems not utilising any glue. DLT utilizes locally sourced material and does not include adhesives it can be considered a natural low carbon value engineered product.

[edit] Related articles on Designing Buildings

- Carpentry.

- Compressive strength of timber lattice columns for low-rise construction.

- Cross laminated timber.

- Nail Laminated timber.

- Engineered bamboo.

- Engineered wood products.

- Facts about forestry.

- Glulam.

- Janka hardness rating scale.

- Laminated veneer lumber LVL.

- Modified wood.

- Nails - a brief history.

- Plywood.

- Predicting service life of timber structures.

- Sustainable timber.

- Testing timber.

- The differences between hardwood and softwood.

- The use of timber in construction.

- Timber frame.

- Timber vs wood.

- Types of timber.

- Types of timber species.

- Whole life carbon assessment of timber.

- Wood around the world.

[edit] External Links

Featured articles and news

Amendment to the GB Energy Bill welcomed by ECA

Move prevents nationally-owned energy company from investing in solar panels produced by modern slavery.

Gregor Harvie argues that AI is state-sanctioned theft of IP.

Heat pumps, vehicle chargers and heating appliances must be sold with smart functionality.

Experimental AI housing target help for councils

Experimental AI could help councils meet housing targets by digitising records.

New-style degrees set for reformed ARB accreditation

Following the ARB Tomorrow's Architects competency outcomes for Architects.

BSRIA Occupant Wellbeing survey BOW

Occupant satisfaction and wellbeing tool inc. physical environment, indoor facilities, functionality and accessibility.

Preserving, waterproofing and decorating buildings.

Many resources for visitors aswell as new features for members.

Using technology to empower communities

The Community data platform; capturing the DNA of a place and fostering participation, for better design.

Heat pump and wind turbine sound calculations for PDRs

MCS publish updated sound calculation standards for permitted development installations.

Homes England creates largest housing-led site in the North

Successful, 34 hectare land acquisition with the residential allocation now completed.

Scottish apprenticeship training proposals

General support although better accountability and transparency is sought.

The history of building regulations

A story of belated action in response to crisis.

Moisture, fire safety and emerging trends in living walls

How wet is your wall?

Current policy explained and newly published consultation by the UK and Welsh Governments.

British architecture 1919–39. Book review.

Conservation of listed prefabs in Moseley.

Energy industry calls for urgent reform.

Comments

[edit] To make a comment about this article, or to suggest changes, click 'Add a comment' above. Separate your comments from any existing comments by inserting a horizontal line.