Chiller units

Chillers are used in buildings to provide cooling. This is typically for heating, ventilation and air conditioning (HVAC) systems providing thermal comfort for occupants, but they can also be used to provide cooling for industrial processes.

Chillers remove heat from a liquid through a refrigeration cycle in a process that is essentially the same as that used to cool domestic fridges. They can work on compression or absorption:

- In compression systems, a liquid refrigerant with a low boiling point absorbs heat from water returning from the building and boils in an evaporator to form a gas. The gas is then compressed, which increases its temperature further. The gas is then condensed, releasing its latent heat which is rejected to the outside. The process then repeats.

- Absorption refrigeration works on a similar basis, with a refrigerant that boils at low temperature and pressure, however, in this case, the refrigerant gas is then absorbed in a solution which is then heated in a ‘generator’ so that the refrigerant evaporates again, but this time at a higher pressure and temperature. The gas is then condensed, releasing its latent heat which is rejected to the outside. The process then repeats.

The rejection of heat from chiller units can be achieved by:

- Air cooling, which rejects heat to the outside air by circulating it through the condenser.

- Evaporative cooing, which uses the addition of a water mist to the air to enhance the cooing effect.

- Water cooling, which is generally suited to large systems and requires connection to cooling towers.

Heat recovery can be used to allow the rejected heat from chiller units to be re-used for space heating or to provide hot water.

The exact opposite of the refrigeration process can be achieved by a heat pump, which reverses the cycle so that heat is supplied to the building rather than cooling. Some systems are reversible, able to supple either heat or cooling. See Heat pump for more information.

Typically in heating, ventilation and air conditioning systems, chiller units produce chilled water that is piped to air handling units (or fan coil units) where it is used to cool the air that ventilates the building. The ‘warmed’ water is then returned to the chiller unit to be re-cooled. The process of cooling ventilation air will also reduce its humidity.

Air handling units may also include a heating coil for times when heating rather than cooling is required. In some situations, air that has already been cooled will be re-heated (typically in simple, single duct constant air volume (VAC) systems). Whilst this may seem wasteful, in buildings where there are some minor local variations in thermal demand it can be more economic than it would be to provide two separate air ducting networks.

Chilled water might be supplied to other components, such as chilled beams, chilled ceilings and so on.

An alternative system supplies the refrigerant itself (rather than chilled water) to terminal units supplying different thermal zones. Variable refrigerant flow (VRF) systems use a single external condensing unit and multiple internal evaporators and can be more efficient, more compact and offer greater flexibility than other HVAC systems. See Variable refrigerant flow for more information.

Some refrigerants have both ozone depletion potential (ODP) and global warming potential (GWP), and as a consequence refrigerants such as CFCs (chlorofluorocarbons) are banned. New equipment using HCFCs ((hydrochlorofluorocarbons such as R22 and R408A) was banned in 2001 (2004 for small systems), and the use of virgin HCFCs was banned in 2010, when it also became illegal to manufacture HCFC refrigerants or for suppliers to keep them in stock. From January 1st 2015 the use of HCFCs was prohibited in any form, even for maintenance. The use of HFCs (hydrofluorocarbons, including 417A, 422A, 422D, 424A, 427A, 428A and 434A) continues to be permitted. Other refrigerants include, ammonia (common in absorption refrigeration), carbon dioxide and non-halogenated hydrocarbons.

It is important that the design of HVAC systems is considered as a part of the overall design process for the building, and not seen as an add on at the end. It is also important that HVAC systems are regularly maintained to ensure optimum performance and occupant comfort.

[edit] Related articles on Designing Buildings

- Absorption chiller.

- Absorption refrigeration.

- Air conditioning inflation and supply chain crisis

- Air conditioning.

- Air handling unit.

- Chilled beam.

- Chlorofluorocarbons CFCs.

- Constant air volume.

- Fan coil unit.

- Heat pumps.

- Heat recovery.

- HVAC.

- Hydrochlorofluorocarbons HCFCs.

- Passive building design.

- Refrigerants.

- Thermal comfort.

- Variable air volume.

- Variable refrigerant flow.

- Ventilation.

Featured articles and news

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

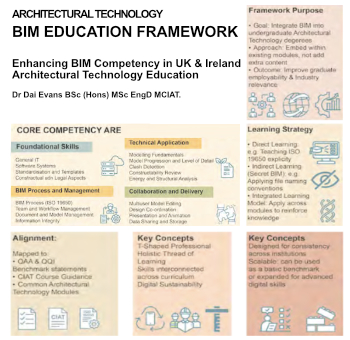

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”

Guidance notes to prepare for April ERA changes

From the Electrical Contractors' Association Employee Relations team.

Significant changes to be seen from the new ERA in 2026 and 2027, starting on 6 April 2026.

First aid in the modern workplace with St John Ambulance.

Ireland's National Residential Retrofit Plan

Staged initiatives introduced step by step.

Solar panels, pitched roofs and risk of fire spread

60% increase in solar panel fires prompts tests and installation warnings.

Modernising heat networks with Heat interface unit

Why HIUs hold the key to efficiency upgrades.

Reflecting on the work of the CIOB Academy

Looking back on 2025 and where it's going next.

Procurement in construction: Knowledge hub

Brief, overview, key articles and over 1000 more covering procurement.

Sir John Betjeman’s love of Victorian church architecture.

Exchange for Change for UK deposit return scheme

The UK Deposit Management Organisation established to deliver Deposit Return Scheme unveils trading name.

A guide to integrating heat pumps

As the Future Homes Standard approaches Future Homes Hub publishes hints and tips for Architects and Architectural Technologists.

BSR as a standalone body; statements, key roles, context

Statements from key figures in key and changing roles.

Resident engagement as the key to successful retrofits

Retrofit is about people, not just buildings, from early starts to beyond handover.

Comments