Plug and play skyscrapers

|

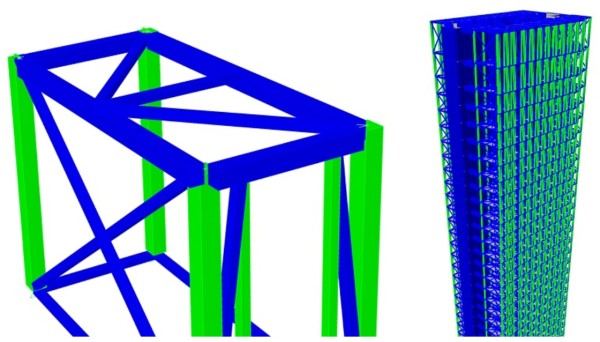

| Typical steel module (left) was modelled in a 40-storey building (right) |

Contents |

[edit] Introduction

Off-site manufacture of ‘plug and play’ modules is fast gaining ground in the housing and plant sectors. What are the engineering challenges for using it for high-rise buildings?

Modular construction, in which complete assemblies – ranging from plant rooms to apartments – are manufactured and tested off-site and then simply slotted into position on-site, is revolutionising construction worldwide.

Benefits include shorter construction, greater safety, reduced waste and higher performance. It comes under various names, including ‘modern methods of construction’ in the UK, ‘permanent modular building’ in the USA, ‘prefabricated prefinished volumetric construction’ in Singapore and ‘modular integrated construction’ in Hong Kong.

[edit] Engineering challenges

However, devising modular systems for high-rise buildings is more technically challenging than those currently used for low- to medium-rise structures, particularly where space is at a premium and strong winds and seismic loading are likely.

Lifting and handling of modules is also a major concern, so reducing module weight is a priority. However, reducing the self-weight may result in excessive tension uplift under strong winds and lead to non-linear behaviour during earthquakes.

In addition, the lateral stability of modular buildings is primarily provided by a reinforced concrete stair and lift core. For high-rise structures, stability can be increased by adding steel outrigger arms to the core and steel edge columns, but analysis of the stresses induced in the modules becomes highly complex.

[edit] Solutions and recommendations

The University of Hong Kong recently carried out a feasibility study for the Hong Kong government on the use of modular construction for high-rise buildings.

Structural schemes for 31–40-storey buildings using commonly-manufactured steel modules were numerically modelled in the Etabs software and analysed against codified critical wind loads.

The results showed that modular high-rise buildings are feasible regarding structural stability – that is, they can satisfy the limitations in top-storey and inter-storey drift due to wind loads.

This however depends on careful design of the core wall layout, core wall thickness and connections between the modules and the core.

Modules with one side directly connected to the core are recommended so that the majority of lateral loads can be transferred to the core by each module independently.

Also, these connections should be designed as pin-ended in the vertical direction. As a lower-bound approach, pin-ended connections were used in the numerical model and were further checked against finite-element analysis using Abaqus in terms of stiffness, load capacity, deformation and stress distribution.

[edit] Higher strength materials

In addition, high-strength steel columns of grades S690 or even S960 can be used for manufacturing the modules to ensure sufficient load-carrying capacity.

For concrete modules, adopting fibre-reinforced concrete walls and/or slabs can help to reduce structural weight to an optimum level.

Authors: Wei Pan, Ray Su, Yancheng Cai and Ben Young, The University of Hong Kong. This article is based on the authors’ briefing article issue 174 CE4 of the ICE Civil Engineering journal. November 2018. Source: https://www.ice.org.uk/news-and-insight/the-civil-engineer/december-2018/plug-and-play-skyscrapers-can-it-be-done

--The Institution of Civil Engineers

[edit] Related articles on Designing Buildings Wiki

- Advanced construction technology.

- Advanced manufacturing.

- BSRIA launches Offsite Construction for Building Services topic guide.

- How to make projects off-site ready.

- ICE articles on Designing Buildings Wiki

- Modern methods of construction.

- Modular buildings.

- Off-site construction.

- Offsite manufacturing.

- Off-site prefabrication of buildings: A guide to connection choices.

- Prefabrication.

- Skyscraper.

- The Institution of Civil Engineers.

Featured articles and news

Moisture, fire safety and emerging trends in living walls

How wet is your wall?

Current policy explained and newly published consultation by the UK and Welsh Governments.

British architecture 1919–39. Book review.

Conservation of listed prefabs in Moseley.

Energy industry calls for urgent reform.

Heritage staff wellbeing at work survey.

A five minute introduction.

50th Golden anniversary ECA Edmundson apprentice award

Showcasing the very best electrotechnical and engineering services for half a century.

Welsh government consults on HRBs and reg changes

Seeking feedback on a new regulatory regime and a broad range of issues.

CIOB Client Guide (2nd edition) March 2025

Free download covering statutory dutyholder roles under the Building Safety Act and much more.

AI and automation in 3D modelling and spatial design

Can almost half of design development tasks be automated?

Minister quizzed, as responsibility transfers to MHCLG and BSR publishes new building control guidance.

UK environmental regulations reform 2025

Amid wider new approaches to ensure regulators and regulation support growth.

The maintenance challenge of tenements.

BSRIA Statutory Compliance Inspection Checklist

BG80/2025 now significantly updated to include requirements related to important changes in legislation.

Shortlist for the 2025 Roofscape Design Awards

Talent and innovation showcase announcement from the trussed rafter industry.

OpenUSD possibilities: Look before you leap

Being ready for the OpenUSD solutions set to transform architecture and design.

Global Asbestos Awareness Week 2025

Highlighting the continuing threat to trades persons.

Retrofit of Buildings, a CIOB Technical Publication

Now available in Arabic and Chinese as well as English.