HVAC Duct Shop Drawings

[edit] 1. Introduction to HVAC Duct Shop Drawings

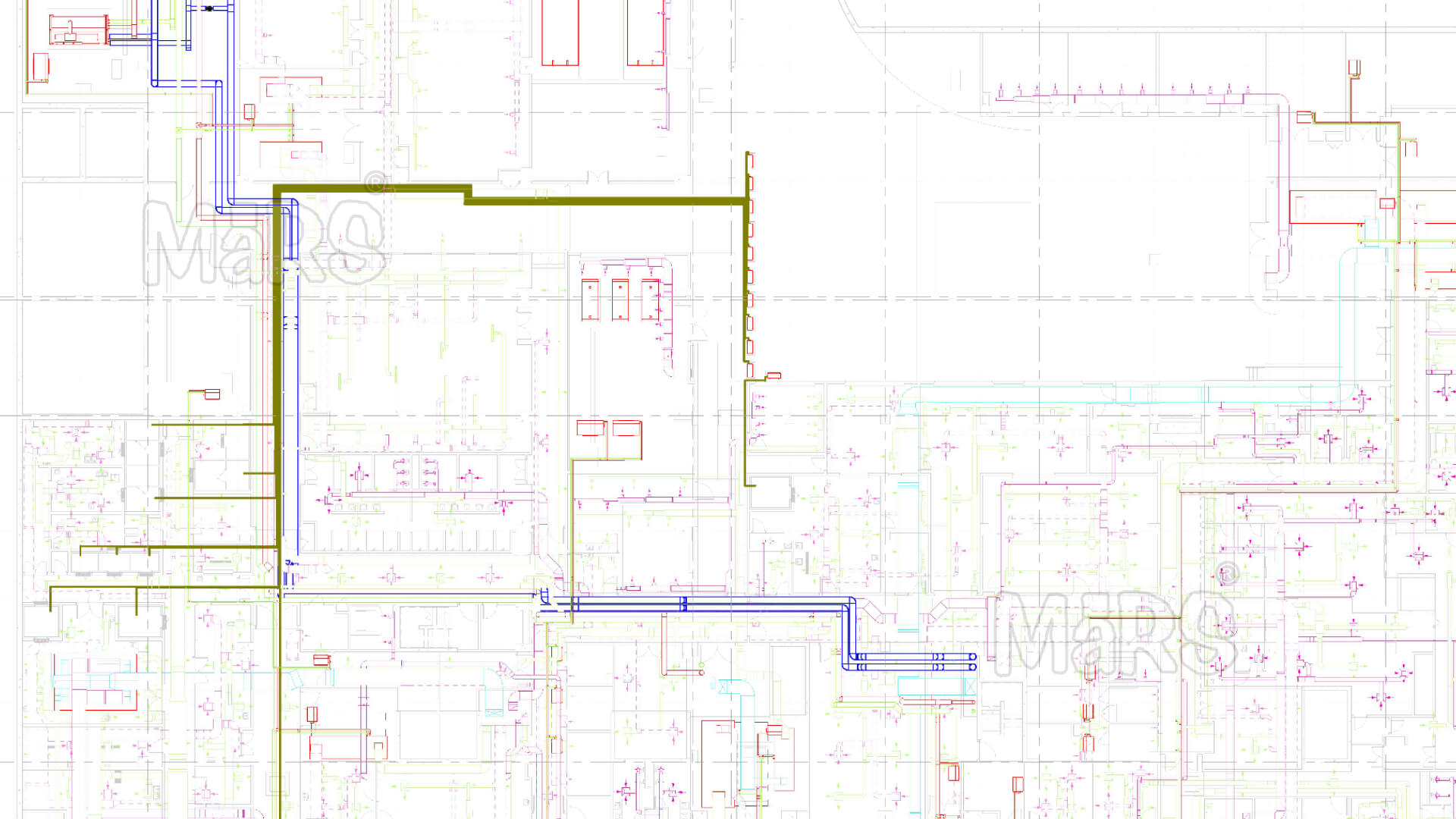

When installing an HVAC system (Heating, Ventilation, and Air Conditioning) in a building, clear planning is essential. HVAC duct shop drawings serve as detailed blueprints, guiding installers and fabricators on the placement and connections of ducts within the building's structure. Essentially, they act as the roadmap for a smooth installation process. With the introduction of MEP BIM Services (Mechanical, Electrical, Plumbing Building Information Modeling), these drawings have become more sophisticated. BIM technology enhances coordination, enables early detection of potential issues (clash detection), and improves visualization of how the ducts interact with other building systems, such as plumbing and electrical work. This guide will walk you through HVAC duct shop drawings and how MEP BIM services enhance accuracy and efficiency.

[edit] 2. Key Elements of HVAC Duct Shop Drawings with MEP BIM Services

2.1. General Information: While HVAC duct shop drawings include essential project information, MEP BIM services boost this process with digital modelling. This integration fosters teamwork, enhances accuracy, and helps prevent costly issues.

- Project Details with BIM Integration: BIM provides stakeholders—HVAC, plumbing, and electrical teams—with real-time access to 3D models and drawings. This ensures everyone is on the same page and can collaborate seamlessly. Changes are instantly reflected across the team, keeping communication clear and reducing mistakes.

- Drawing Title and Number: Unlike static drawings, BIM models are linked to dynamic schedules. Updates flow through the entire model automatically, ensuring that on-site plans are always current, which minimises fabrication and installation errors.

2.2. Duct Layout and Routing: MEP BIM services elevate duct layout and routing by creating a 3D environment that enhances precision and reduces potential delays.

- 3D Modelling of Ducts: BIM allows for immersive 3D modelling, enabling designers and installers to see how ducts will fit within the building structure, helping avoid spatial conflicts and optimising available space.

- Clash Detection: BIM's automated clash detection identifies potential conflicts between HVAC ductwork and other systems (like electrical or plumbing) early in the design phase, saving time and costs during construction.

- Real-Time Coordination: Platforms like Revit facilitate real-time collaboration among HVAC, plumbing, and electrical teams, ensuring that duct routes and fittings are accurately aligned, which reduces misunderstandings and design conflicts.

[edit] 3. Airflow Information and Duct Performance Enhanced by BIM

3.1. Accurate Airflow Calculations: BIM simplifies airflow calculations (CFM) for each duct segment, directly linking them to the model. Design changes, such as duct size adjustments, instantly reflect in airflow data, minimising manual calculation errors and ensuring system requirements are met.

3.2. Pressure Ratings and System Optimisation BIM enables performance simulations to optimise duct routing for static and dynamic pressure. This ensures efficient ductwork design, reducing pressure drops and enhancing energy efficiency for a more comfortable indoor environment.

3.3. Smart Dampers and Controls Integrating smart dampers within the BIM model allows for easy configuration and control, facilitating automation of the HVAC system. This integration ensures dampers fit perfectly into the overall design and work seamlessly with other building automation systems.

[edit] 4. Integration of Diffusers, Grilles, and Registers through BIM

4.1. Enhanced Placement Accuracy MEP BIM services enable precise placement of diffusers, grilles, and registers in a detailed 3D environment, ensuring optimal positioning for maximum efficiency and minimising rework during installation.

4.2. Performance Simulations BIM's capability for airflow simulations allows designers to verify that air distribution meets comfort and efficiency standards before construction begins. This proactive approach helps detect and resolve potential imbalances early on.

[edit] 5. Advanced Coordination with Other Building Systems via BIM

5.1. Improved Interference Checks MEP BIM services excel at detecting clashes before installation, allowing designers to identify potential conflicts between HVAC ducts and other systems well in advance, leading to a smoother installation process.

5.2. Seamless Integration with Electrical and Plumbing Systems Integrating HVAC with other MEP services in a BIM model provides a comprehensive view of how ducts, pipes, and electrical wiring coexist, minimising unexpected challenges during installation.

5.3. Digital Maintenance Planning BIM models include precise locations for access panels and equipment, simplifying future maintenance tasks and ensuring long-term efficiency.

[edit] 6. Construction and Fabrication Details in a BIM Environment

6.1. Prefabrication Using BIM BIM allows contractors to generate ready-to-install duct sections directly from the model, improving accuracy and reducing material waste while speeding up installation.

6.2. Automated Updates and Version Control Any changes to duct layouts or specifications are automatically updated in the BIM model, ensuring all stakeholders work with the latest information.

6.3. Accurate Hanger and Support Placement BIM provides exact dimensions and placement details for hangers and supports, allowing for efficient pre-installation and a quick assembly process.

[edit] 7. Fire and Smoke Control with BIM Services

7.1. Fire and Smoke Damper Integration BIM effectively integrates fire and smoke dampers into the overall safety model, enhancing coordination between fire protection and HVAC systems.

7.2. Code Compliance Verification BIM helps ensure fire safety code compliance by automatically checking if dampers, fire walls, and duct penetrations meet regulations, giving stakeholders peace of mind.

[edit] 8. Quality Assurance and Testing with BIM

8.1. Virtual Testing and Balancing BIM enables virtual testing and balancing (TAB) of HVAC systems, allowing designers to ensure everything is adjusted before installation, leading to a smoother on-site process.

8.2. Automated Inspection and Maintenance Data BIM simplifies inspections by embedding inspection points and requirements into the model, helping maintenance crews easily find the information they need.

[edit] 9. BIM-Driven Legends, Symbols, and Documentation

9.1. Intelligent Symbol Representation In BIM-driven shop drawings, symbols for ducts, fittings, and equipment are linked to their 3D components, making it easier to understand the system's layout.

9.2. Data-Driven Equipment Tags Each component includes a detailed data tag in the BIM model, linking directly to schedules and specifications, enhancing accuracy during procurement and installation.

[edit] 10. Role of MEP BIM in HVAC Duct Shop Drawings

Using MEP BIM services in HVAC duct shop drawings has transformed design, fabrication, and installation processes. With tools like 3D modelling, real-time coordination, and virtual performance simulations, BIM provides a level of accuracy and efficiency previously unattainable. By utilising BIM, stakeholders can ensure that HVAC systems meet design requirements and integrate seamlessly with other building systems, leading to smoother and more successful project outcomes. It’s all about collaborating to create comfortable, efficient, and well-integrated spaces.

--Snehal Dodha 06:32, 26 Sep 2024 (BST)

[edit] Related articles on Designing Buildings

- Artificial intelligence.

- Beyond BIM: Knowledge management for a smarter built environment.

- BIM articles.

- BIM and facilities management.

- BIM for mechanical electrical and plumbing drawings.

- Building information modelling BIM.

- Global BIM market.

- How BIM can cause needless early stage MEP design concerns.

- Mechanical, electrical and plumbing MEP.

- MEP Coordination.

- MEP BIM and the building lifecycle

- Revit.

- Sustainability in building design and construction.

- The sustainability of construction works.

- UsBIM.

- Integrating Scan to BIM for Sustainable Smart City Planning.

- Scan to BIM in Construction

- Scan to BIM: Everything you need to know.

BIM Directory

[edit] Building Information Modelling (BIM)

[edit] Information Requirements

Employer's Information Requirements (EIR)

Organisational Information Requirements (OIR)

Asset Information Requirements (AIR)

[edit] Information Models

Project Information Model (PIM)

[edit] Collaborative Practices

Industry Foundation Classes (IFC)