Brass

Contents |

[edit] Introduction

Brass is an alloy of copper and some form of zinc. Its appearance is similar to less refined forms of gold, but it is much stronger and cheaper.

[edit] History

Brass has been made since prehistoric times and has been used by many civilisations. Passing references to very early versions of the material date back as far as Ancient Greece (during the 8th–7th century BC), and there are additional examples from the 5th century BC found in China.

Brass became more widely used during the late Roman era (roughly around the 1st century AD) when the material was often used for coinage, military equipment, vessels for eating and drinking as well as other objects. Most of these early brass items were made with calamine instead of pure zinc. Calamine is the term used for the two zinc oxides known as smithsonite or hemimorphite.

In the period leading up to the Middle Ages, brass continued to be used in Islamic and Byzantine cultures. Its popularity in much of Western Europe declined until the medieval period, when demand for brass work once again increased. Many of the brass objects that were produced during this period were made from calamine ore found in the mines located in Germany, France and Flanders. Items such as domestic utensils and candlesticks could be procured by members of wealthier medieval households, and fine brass objects were also popular for religious purposes.

By the 16th century, the need for brass in England increased. This was due to the demand for brass-wire combs used by the wool industry. Widespread production of brass expanded towards the end of the 17th century as the material was used in the manufacture of even more common items.

By the 1800s, zinc had been purified and the resulting improvement in the new brass gave it qualities more suitable for casting processes. Birmingham (England) became almost a generic name for brass articles of all kinds which were sent around the world. Some fine brass castings were gilded or even plated with silver and then varnished to prevent tarnishing.

[edit] Modern uses of brass

Modern brass items are made in lighter alloys while items that have been made in the traditional manner are considered luxury items.

Some uses of brass in the built environment include:

- Architectural ironmongery or hardware such as door knobs, finger plates and other door furniture for use in all types of buildings. (These should not be painted, as there are clear lacquers that can protect these items from the elements.)

- Brass solders that use copper-zinc alloys.

- Plumbing materials such as pipes, joints, taps, stopcocks. Brass pipes may corrode due to the zinc content of the metal, so it’s important to use corrosion-resistant brass to avoid electro-chemical reactions with copper pipes).

- Screws, nails and other fastening devices.

- Furniture, clocks, decorative objects and so on.

Modifications to the proportions of copper and zinc can result in types of brass with different mechanical, electrical and chemical characteristics. One type of specialty brass is a material referred to as ormolu. Originally this referred to metalwork that involved a form of gilding that used a high-carat gold–mercury amalgam on a bronze object. It was easy to cast and was usually associated with elaborate French furniture and metal parts made in the 18th and 19th centuries. Due to the toxic nature of the mecury vapour created during the process, the technique fell out of fashion and was outlawed in the 1800s. The term has since been used to describe a fine type of brass alloy, using equal parts of copper, zinc and tin, or copper and zinc alone.

[edit] Restoring brass

Over time, brass can corrode to a dull brown colour. This form of corrosion is normally easy to remove with a standard metal polish.

Badly weathered brass can develop green deposits called verdigris. This form of heavy corrosion may leave the metal pitted, so it should be cleaned as soon as possible.

[edit] Related articles on Designing Buildings

Featured articles and news

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description fron the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

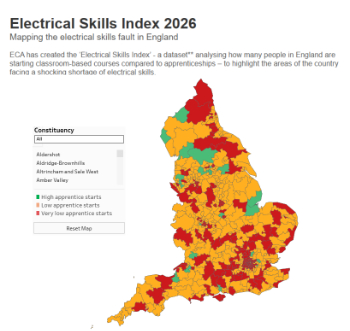

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

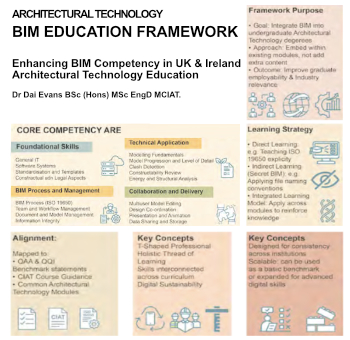

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”

Guidance notes to prepare for April ERA changes

From the Electrical Contractors' Association Employee Relations team.

Significant changes to be seen from the new ERA in 2026 and 2027, starting on 6 April 2026.

First aid in the modern workplace with St John Ambulance.

Solar panels, pitched roofs and risk of fire spread

60% increase in solar panel fires prompts tests and installation warnings.

Modernising heat networks with Heat interface unit

Why HIUs hold the key to efficiency upgrades.