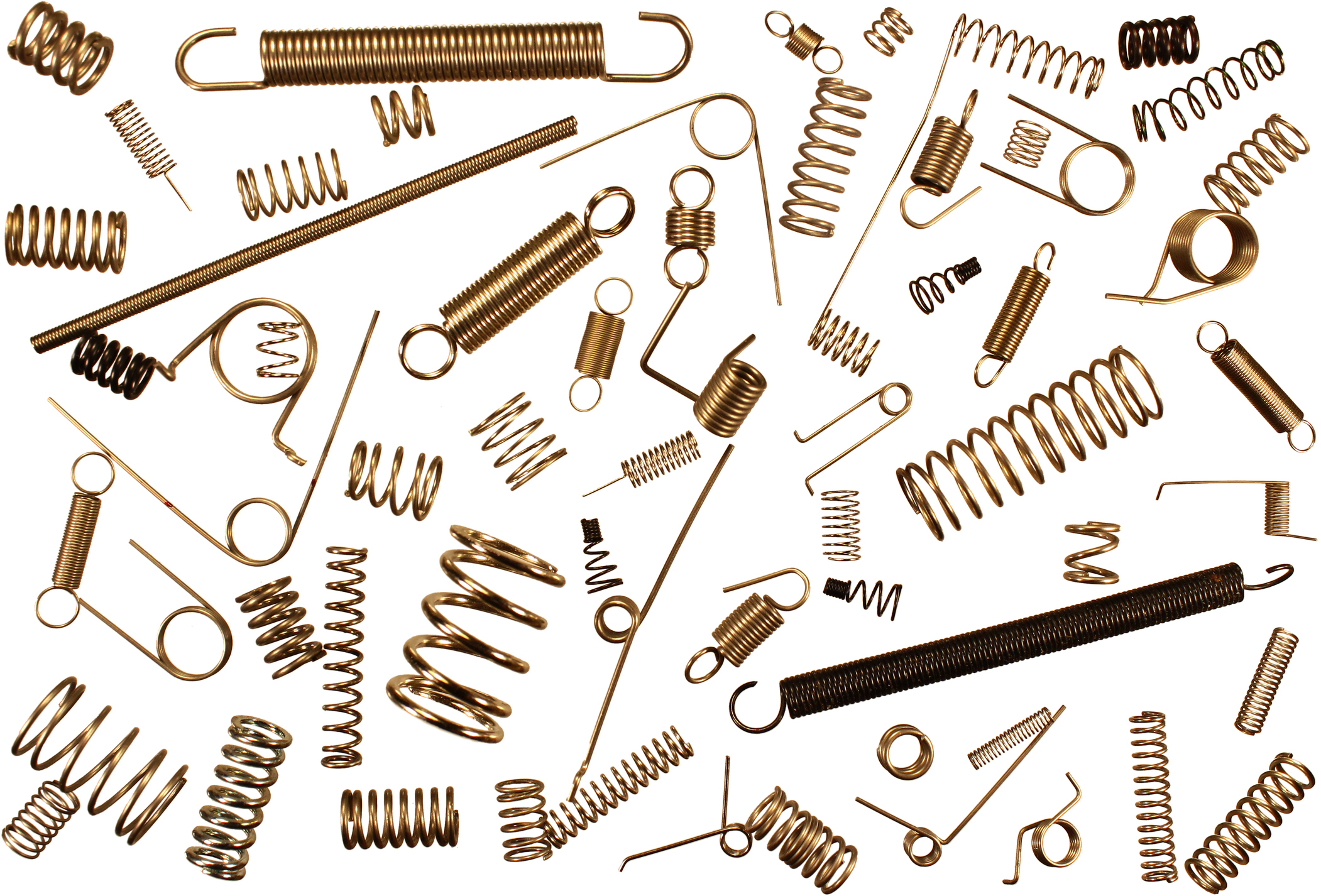

Spring materials

Contents |

[edit] Introduction

Springs are used in a huge range of different applications and are created in a variety of shapes, sizes and materials in order to fulfil different requirements. These different spring materials are used based on the requirements of the spring and present their own advantages and disadvantages.

While some materials boast a high resistance to corrosion, others may present a strength advantage. As technology advances, manufacturers and engineers are looking to create materials that are capable of being used in applications that may never have been necessary before, such as aerospace.

[edit] Stainless steel

Stainless steel is a commonly used alloy which is used in a huge range of applications. Stainless steels have a minimum of 10.5% chromium and other alloying elements are added to enhance the structure. This material is known for its excellent corrosion resistance so it is often used in architectural applications.

As a spring material, stainless steels are a popular choice due to their corrosion and heat resistance. These qualities mean that the alloy can maintain its integrity and remain strong in a number of applications where other materials may fail or degrade.

[edit] Alloy steels

Alloy steels are steels which have one or more alloying elements added to them in order to improve their properties. They may feature alloys such as manganese, silicon, nickel, titanium, copper, chromium or aluminium, to name a few.

Alloy steels often have improved strength, toughness, corrosion resistance, hardenability and hot hardness. This means that they are often used in applications that require a great deal of hardiness, such as in the aerospace and military fields.

[edit] Titanium alloys

Titanium alloys are made up of a mixture of titanium and other chemical elements. They are divided into grades which differentiate their properties and benefits such as formability and ductility.

This material tends to be lightweight even though other properties include extreme corrosion and heat resistance. Due to the hardwearing qualities of this material, it is often used in applications including aerospace, medical and automotive.

[edit] Copper alloys

Copper alloys are primarily composed of copper but have other metals added to create varying alloys with different properties and benefits. Bronze is the best-known copper alloy, and brass is another example.

These alloys have a high resistance to corrosion. Aluminium bronzes are particularly high in strength and corrosion resistance and can often be found in marine applications.

[edit] Super-alloys

Super-alloys benefit from the following characteristics:

- Excellent mechanical strength.

- Resistance to thermal creep deformation.

- Good surface stability.

- Resistance to corrosion or oxidation.

Due to these qualities, super-alloys are most commonly used in particularly high-stress applications, such as in the aerospace and marine sectors.

[edit] Related articles on Designing Buildings

- Bronze.

- Compression springs.

- E-Spring.

- Extension Springs.

- Flat springs.

- Key qualities of springs.

- Tension springs v torsion springs.

- The Importance of Gas Springs.

- Using springs in construction to prevent disaster.

--European Springs and Pressings Ltd 13:59, 16 Aug 2017 (BST)

Featured articles and news

Homes England creates largest housing-led site in the North

Successful, 34 hectare land acquisition with the residential allocation now completed.

Scottish apprenticeship training proposals

General support although better accountability and transparency is sought.

The history of building regulations

A story of belated action in response to crisis.

Moisture, fire safety and emerging trends in living walls

How wet is your wall?

Current policy explained and newly published consultation by the UK and Welsh Governments.

British architecture 1919–39. Book review.

Conservation of listed prefabs in Moseley.

Energy industry calls for urgent reform.

Heritage staff wellbeing at work survey.

A five minute introduction.

50th Golden anniversary ECA Edmundson apprentice award

Showcasing the very best electrotechnical and engineering services for half a century.

Welsh government consults on HRBs and reg changes

Seeking feedback on a new regulatory regime and a broad range of issues.

CIOB Client Guide (2nd edition) March 2025

Free download covering statutory dutyholder roles under the Building Safety Act and much more.

Minister quizzed, as responsibility transfers to MHCLG and BSR publishes new building control guidance.

UK environmental regulations reform 2025

Amid wider new approaches to ensure regulators and regulation support growth.

BSRIA Statutory Compliance Inspection Checklist

BG80/2025 now significantly updated to include requirements related to important changes in legislation.