Polytunnel

Contents |

[edit] What are polytunnels?

Polytunnels, also known as hoop houses or high tunnels, are agricultural structures made of a series of metal hoops covered with a polyethylene film. They are generally used to extend the growing season and protect crops from harsh weather conditions.

[edit] What is the history of polytunnels?

The concept of using tunnels to protect crops dates back to the early 19th century, when gardeners in France and England used glass frames to create small greenhouses. In the early 20th century, growers in the United States began using metal hoops covered with cloth or burlap to create low tunnels to protect crops from frost.

The first polyethylene-covered tunnels were developed in the 1950s by Emery Emmert, a horticulturist at the University of Kentucky. Emmert recognised that the transparent plastic film could provide a cost-effective way to protect crops from weather-related damage while also allowing for greater control over the growing environment.

In the decades that followed, polytunnels became increasingly popular among small-scale farmers and gardeners, as well as larger commercial operations. Advances in technology, such as the development of more durable and UV-resistant polyethylene films, have made them even more versatile and cost-effective.

Today, polytunnels are used around the world to extend the growing season, protect crops from pests and diseases, and provide a controlled environment for seedling propagation. They are an important tool for small-scale farmers and gardeners who are looking to increase their yields and improve their bottom line.

[edit] What are polytunnels made from?

Polytunnels are typically made from a series of metal hoops or arches that are covered with a polyethylene film. The hoops or arches are usually made from galvanised steel, aluminium, or polyvinylchloride (PVC) pipe. They are anchored into the ground with posts or stakes.

The plastic film is typically made from high-density polyethylene (HDPE) or low-density polyethylene (LDPE). This is lightweight, strong, and durable, and allows sunlight to pass through while protecting the crops inside from wind, rain, and other weather conditions.

The plastic film is available in a range of thicknesses, from 0.3mm to 1mm or more. The thicker the film, the more durable it will be and the longer it will last. UV-resistant films are also available to help protect the plastic from sun damage, which can cause it to degrade and become brittle over time.

Polytunnels may also include components such as end walls, doors, and ventilation systems to control the environment inside. These components can be made from a variety of materials, such as wood, metal, and plastic.

[edit] What are the pros and cons of polytunnels?

Advantages of polytunnels include:

- Extended growing season, allowing crops to be grown earlier in the spring and later into the autumn. This can increase the yield and variety of crops produced.

- They can protect crops from harsh weather conditions, such as heavy rain, hail, and wind. They can also prevent damage from extreme temperatures, including frost and heatwaves.

- They can help prevent pests and diseases from damaging crops by creating a physical barrier between the crops and the external environment.

- They provide a controlled growing environment, allowing control over temperature, humidity, and ventilation. This can produce more consistent crop yields and higher-quality produce.

- They can be a more cost-effective alternative to greenhouses or other permanent structures, and they can require less maintenance.

Disadvantage of polytunnels include:

- Cost: While polytunnels are less expensive than greenhouses, they still require an initial investment to construct.

- While polytunnels can protect crops from some weather events, they may not withstand extreme weather conditions such as heavy snow, high winds, or hurricanes.

- They may be less effective for large-scale production due to their limited growing space.

- They require regular maintenance to ensure that the plastic covering remains taut and free of damage.

- They can create a humid environment that may be conducive to the growth of mould and other fungi, which can be harmful to crops.

[edit] What are the environmental consequences of using polytunnels?

Polytunnels can have both positive and negative impacts on the environment, depending on how they are used and managed.

Positive impacts:

- By providing a physical barrier to pests, they can reduce the need for chemical pesticides, which can be harmful to the environment and human health.

- They can be used to collect and conserve rainwater, reducing the need for irrigation.

- They can reduce the carbon footprint of agriculture by extending the growing season and allowing farmers to produce crops locally, rather than importing them.

Negative impacts:

- Polyethylene plastic film is not biodegradable, and when it is no longer usable, it must be disposed of properly to avoid environmental pollution.

- Intensive use of polytunnels can lead to soil degradation, particularly if the same crop is grown repeatedly in the same area, leading to a decline in soil fertility and an increase in pests and disease pressure.

- Polytunnels can use energy to heat and ventilate them, particularly in colder climates. This can result in increased carbon emissions and energy costs.

To minimise the negative impacts of polytunnels, steps can be taken to manage the use of plastic and protect soil health by rotating crops and using organic soil amendments. Additionally, they can employ energy-efficient heating and ventilation systems and use rainwater harvesting techniques to reduce their water consumption.

[edit] Related articles on Designing Buildings

Featured articles and news

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

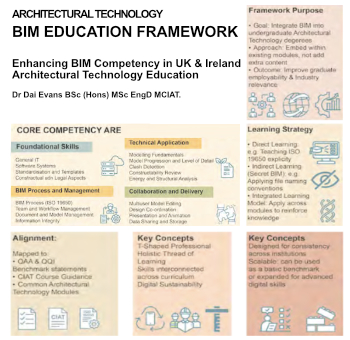

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”

Guidance notes to prepare for April ERA changes

From the Electrical Contractors' Association Employee Relations team.

Significant changes to be seen from the new ERA in 2026 and 2027, starting on 6 April 2026.

First aid in the modern workplace with St John Ambulance.

Ireland's National Residential Retrofit Plan

Staged initiatives introduced step by step.

Solar panels, pitched roofs and risk of fire spread

60% increase in solar panel fires prompts tests and installation warnings.

Modernising heat networks with Heat interface unit

Why HIUs hold the key to efficiency upgrades.

Reflecting on the work of the CIOB Academy

Looking back on 2025 and where it's going next.

Procurement in construction: Knowledge hub

Brief, overview, key articles and over 1000 more covering procurement.

Sir John Betjeman’s love of Victorian church architecture.

Exchange for Change for UK deposit return scheme

The UK Deposit Management Organisation established to deliver Deposit Return Scheme unveils trading name.

A guide to integrating heat pumps

As the Future Homes Standard approaches Future Homes Hub publishes hints and tips for Architects and Architectural Technologists.

BSR as a standalone body; statements, key roles, context

Statements from key figures in key and changing roles.

Resident engagement as the key to successful retrofits

Retrofit is about people, not just buildings, from early starts to beyond handover.