Curved intersections and accentuated water ingress

|

| Written by John Shillabeer. Cavity Trays Ltd. |

Contents |

[edit] Curved cavity walls and spherical corners intersecting pitched roofs.

Where the requirement is to integrate an abutting sloping roof with concave or convex masonry, a number of considerations arise:

[edit] In the wall

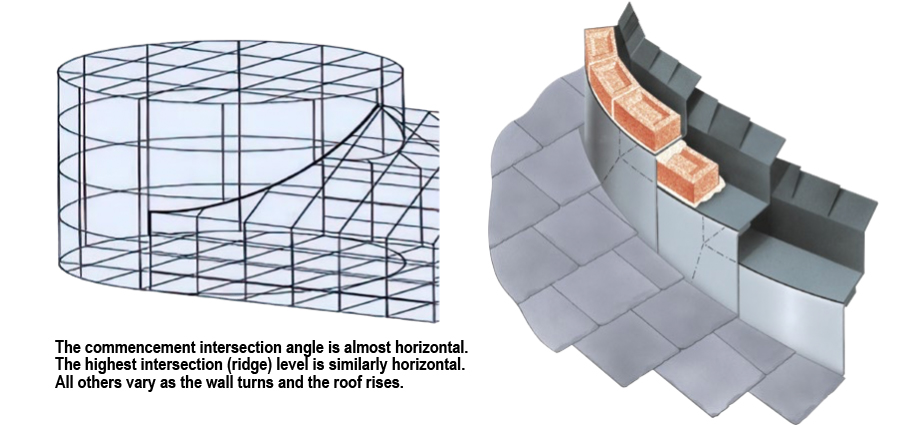

The DPC within the cavity wall and the corresponding flashing need to be of a different shape and a different size at every intersecting course, regardless of the masonry coursing remaining regular. This is because the actual angle of intersection changes, despite the roof pitch remaining constant.

To provide the DPC protection within the wall, fabricating course by course on site using roll material is time-consuming and an almost impossible task. Roll DPC also requires support by building-into the inner skin, and where the inner skin is blockwork, it offers fewer conveniently located courses!

As continuous protection is required, each course level must link with its higher neighbour, to create within the cavity wall, protection resembling a staircase with connecting DPC treads and connecting DPC risers. At the same time, protection must horizontally project through the outer skin course and align with the face of the turning wall. It is not possible to stretch or shrink roll DPC to achieve this.

[edit] Outside the wall

Externally a flashing is required to act as a waterproof medium to fulfil two functions. It must positively link within each course with the horizontal DPC, and it must externally flash and integrate with the roof finish to provide a weatherproof join.

It is worth at this point qualifying how water behaves when it strikes the masonry surface of concave and convex walls. Water tends to be blown predominately around a convex wall, with the surface water gravitating as the leeward side is approached. The amount of water- wash traversing the curved wall accelerates on its angled downward path.

In contrast, water blown into an acute concave area has difficulty in dissipating. With both concave and convex walls, it is not uncommon for flashings to experience far higher volumes of surface water wash than is experienced with straight wall intersections. Surface water deflection in both instances increases water wash blowing into flashings, as well as away from flashings. It is important the protection of the intersection takes this into account.

Where an angled roof intersects a curved wall, each individual component is designed to exactly match the dimensional requirements at every intersecting course. These are called Type X cavitrays for curved walls.

The advantages of using preformed cavitrays are numerous:

- Fabrication on site is eliminated – there is no measuring, no cutting and no wastage. Preformed also means the shape is already determined – installer mistakes or oversights need not be a consideration.

- Each cavitray has its own adjustable cavity upstand.

- There is no requirement to locate and build into an inner skin course as upstands are self-supporting. The upstands accommodate the as-built cavity width as opposed to the as intended.

- Every tray has an integral end upstand that rises within the masonry at the inboard end to provide a vertical link to the tray above. Thus, as each tray is laid it integrates with the adjacent tray, creating a linked DPC staircase.

- Where trays are supplied with the flashing already attached the traditional need to rake out joints and introduce flashings separately is eliminated. The union is pre-established.

- Because each cavitray and flashing overlaps the next cavitray and flashing, any wind-driven rain that seeps under a vertically dressed flashing leading edge does not come into contact with the masonry under (unlike conventionally cut running flashings).

- The overlap configuration provides a secondary layer to arrest such water, preventing it from permeating towards and under the adjacent sloping roofline.

- Each tray is numbered and the mason has only to numerically build in trays as the wall is raised. Petheleyne is used for the manufacture of each tray, having been identified as the most accommodating and durable of all DPC materials tested for such purposes. The external flashing may be selected from either lead or a BBA approved synthetic alternative.

Cavity Trays Ltd undertakes to calculate concave and convex abutment requirements / schedules for clients. Other curved cavitrays solutions include; parapet walls, common openings, changes of level, threshold integrity trays.

Cavity Trays produces curved trays for use at various levels of the building envelope.

This article first appeared in CIAT's AT Journal, issue number 141, in Spring 2022.

--CIAT

[edit] Related articles on Designing Buildings

Featured articles and news

Gregor Harvie argues that AI is state-sanctioned theft of IP.

Many resources for visitors aswell as new features for members.

Using technology to empower communities

The Community data platform; capturing the DNA of a place and fostering participation, for better design.

Heat pump and wind turbine sound calculations for PDRs

MCS publish updated sound calculation standards for permitted development installations.

Homes England creates largest housing-led site in the North

Successful, 34 hectare land acquisition with the residential allocation now completed.

Scottish apprenticeship training proposals

General support although better accountability and transparency is sought.

The history of building regulations

A story of belated action in response to crisis.

Moisture, fire safety and emerging trends in living walls

How wet is your wall?

Current policy explained and newly published consultation by the UK and Welsh Governments.

British architecture 1919–39. Book review.

Conservation of listed prefabs in Moseley.

Energy industry calls for urgent reform.

Heritage staff wellbeing at work survey.

A five minute introduction.

50th Golden anniversary ECA Edmundson apprentice award

Showcasing the very best electrotechnical and engineering services for half a century.

Welsh government consults on HRBs and reg changes

Seeking feedback on a new regulatory regime and a broad range of issues.

CIOB Client Guide (2nd edition) March 2025

Free download covering statutory dutyholder roles under the Building Safety Act and much more.