Alkali-activated cementitious material

Contents |

[edit] What is a Alkali-Activated Material or Cementitious Material ?

Alkali-Activated Materials (AAM) or more specifically Alkali-Activated Cementitious Materials (AACM) might also be referred to as geopolymers, they can be created from a range of different materials, most usually from industrial by-products, termed precursors. These are added to an alkaline medium or activator, to produce a cementitious material that can be used instead of Portland Cement in the making of concrete.

[edit] Background

It was in 1957, when a scientist from Kyiv, Ukraine (which was then part of USSR), Victor Glukhovsky, put forward a working hypothesis in which he established that there was close relationship between alkalis and cementitious materials. He investigated the production of binders by using low basic or free calcium alumino-silicate source (clay) with alkaline activators, the new binder was referred to as soil–cement or soil silicate concretes. It was his assumptions and investigations that formed the foundation on which new types of cementitious materials could be developed, which were later called alkaline cements and later still referred to as AAC's or AACMs.

It was around the 1970's that AAMs were first industrially produced for use as cementitious materials, they had a lower carbon footprint, because the reaction could happen at room temperature and could also contribute to the early ideas around the circular economy because it was possible to use industrial by-products as the raw materials. The term and concept of geopolymer was developed more specifically by Joseph Davidovits, later in 1991, and with ongoing developement in the field, definitions of what a geopolymer is have become gradually more diverse and at times somewhat conflicting.

[edit] Chemical reaction

Alkali-activation is the chemical reaction between a solid aluminosilicate precursor and an alkaline source or activator, importantly it can occur at room temperature to produce a hardened product. The most commonly used alkali sources are sodium or potassium hydroxides and/or silicates, while aluminosilicates may include suitable raw materials and waste products.

The Concrete Society describe alkali activated cements (including geopolymer cements) as:

"The aluminate-containing material - the pozzolan/latent hydraulic binder component of the cement - can be coal fly ash, municipal solid waste incinerator ash (MSWIA), metakaolin, blastfurnace slag, steel slag or other slags, or other alumina-rich materials. The alkali used as the activator tends to be an alkali silicate solution such as sodium silicate (waterglass) but can also be sodium hydroxide solution, or a combination of the two, or other source of alkali (such as lime). Geopolymeric cements are particular examples of ´alkali-activated pozzolanic cements´ or ´alkali-activated latent hydraulic cements´. All alkali-activated cements tend to have lower embodied energy / carbon footprints than Portland cements (up to 80-90% but this is pozzolan dependent). Manufacture on a commercial basis is underway in the UK, Australia, USA and possibly, China. Covered by PAS 8820:2016 Construction materials. Alkali activated cementitious material and concrete. Specification"

[edit] Related articles on Designing Buildings

Featured articles and news

CLC and BSR process map for HRB approvals

One of the initial outputs of their weekly BSR meetings.

Building Safety Levy technical consultation response

Details of the planned levy now due in 2026.

Great British Energy install solar on school and NHS sites

200 schools and 200 NHS sites to get solar systems, as first project of the newly formed government initiative.

600 million for 60,000 more skilled construction workers

Announced by Treasury ahead of the Spring Statement.

The restoration of the novelist’s birthplace in Eastwood.

Life Critical Fire Safety External Wall System LCFS EWS

Breaking down what is meant by this now often used term.

PAC report on the Remediation of Dangerous Cladding

Recommendations on workforce, transparency, support, insurance, funding, fraud and mismanagement.

New towns, expanded settlements and housing delivery

Modular inquiry asks if new towns and expanded settlements are an effective means of delivering housing.

Building Engineering Business Survey Q1 2025

Survey shows growth remains flat as skill shortages and volatile pricing persist.

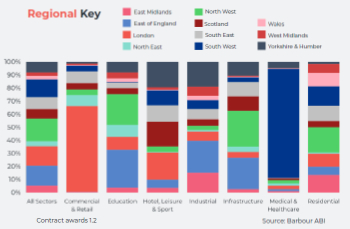

Construction contract awards remain buoyant

Infrastructure up but residential struggles.

Home builders call for suspension of Building Safety Levy

HBF with over 100 home builders write to the Chancellor.

CIOB Apprentice of the Year 2024/2025

CIOB names James Monk a quantity surveyor from Cambridge as the winner.

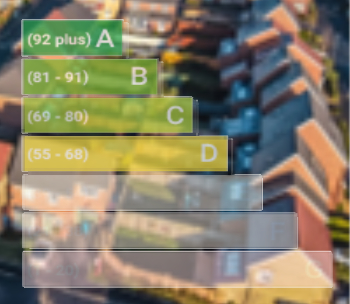

Warm Homes Plan and existing energy bill support policies

Breaking down what existing policies are and what they do.

Treasury responds to sector submission on Warm Homes

Trade associations call on Government to make good on manifesto pledge for the upgrading of 5 million homes.

A tour through Robotic Installation Systems for Elevators, Innovation Labs, MetaCore and PORT tech.

A dynamic brand built for impact stitched into BSRIA’s building fabric.

BS 9991:2024 and the recently published CLC advisory note

Fire safety in the design, management and use of residential buildings. Code of practice.