Paint

Contents |

[edit] Introduction

Paint is a liquid or mastic material that can be applied to surfaces to colour, protect and provide texture. They are usually stored as a liquid and dry into a thin film after application. Paints be categorised decorative, are applied on site, or industrial, applied in factories as part of the manufacturing process.

Some of the attributes normally required from a paint include:

- Capable of easy application.

- Good flow out of application marks (e.g. brush-marking).

- Capable of forming a continuous protective film.

- High opacity.

- Quick drying.

- Corrosion resistance.

- Water and heat resistance.

- Colour stability against visible and ultraviolet radiation.

- Abrasion and scratch resistance.

- Durability.

- Flexibility.

- Easily cleaned.

Paints can be applied with a brush or roller, or by dipping, flowcoating, spraying, hot spraying, electrostatic spraying, airless spraying, electrodeposition, powder coating, vacuum impregnation, immersion, and so on.

[edit] The constituents of paint

Paints may be manufactured using pigments, binders, extenders, solvents and additives.

The pigments provide the paint with its colour and opacity. Pigments can be made of either organic or inorganic derivatives. The pigment powder is broken down into individual particles which are coated by and dispersed in a binder (resin), in a process known as 'wetting out'.

The binder is a polymer which forms a matrix to hold the pigment in place. The three most commonly-used binders are:

An organic solvent is added to achieve the required consistency, improving the application of the paint to reduce its viscosity.

Extenders may also be added. These larger pigment particles provide improved adhesion and strengthen the film.

Depending on the intended use of the paint, other additives may be used to modify the properties of the liquid paint or dry film:

- Driers: For speeding up the drying time.

- Silicones: To improve the paint’s resistance to weather.

- Dispersants: To separate and stabilise pigment particles.

- Thixotropic agents: These provide paints with a thick consistency.

- Anti-settling agents: These are used to prevent the pigment from settling.

- Bactericides: These act as a preservative when the paint is in the can.

- Fungicides and algaecides: Protect paint films from mould, algae and lichen.

[edit] Types of paint

Oil-based paint, also described as ‘enamel’, is commonly used for exteriors, timber and metal due to its hardness and durability. It can create a glossy finish to surfaces. Oil-based enamel tends to dry between 8-24 hours depending on ventilation and humidity conditions. Interior Paint, A guide to internal paint finishes, published on 1 January 2007 by Historic Scotland, states: ‘Traditional oil based paints were very flexible, resisted cracking and gave a greater depth of colour and texture to the surface than modern paints. They were used primarily on joinery and ironwork. Due to the bold colours and versatile range of finishes achievable. Finishes ranged from ‘flatted’ matt to glossier sheens (achieved by varying the ratio of oil to binder), although the effect was different from today’s high sheen gloss paints.’

Water-based paint, also described as ‘latex paint’ or ‘acrylic’ if the binding ingredient is a form of acrylic, takes less time to dry than oil-based, however, they are less glossy and are often less durable.

Very generally, oil-based paints can be applied onto water-based paints, but water-based paints cannot be applied onto oil-based paints.

Although not strictly paint, primer is often required as a component when working with paint. Oil-based paint will require an oil-based primer, and water-based paint will require a water-based primer.

[edit] Paint finishes

[edit] Matte paint

The most common interior wall finish is ‘matte’, which is easy to apply using a brush or roller, and doesn’t provide a distracting shine or sheen to the finish. A solid colour is often achieved through applying more than one single coat. However, matte paint is easily marked and requires regular retouching.

[edit] Eggshell and satin

An eggshell finish has a very subtle shine but without the same smoothness as a satin finish. As they are only partially reflective, they do not highlight imperfections making them suitable as interior wall paint. They are easy to apply and can often cover well with a single coat. They are frequently used in demanding environments such as kitchens and bathrooms, where they provide some water resistance, and can be cleanable.

[edit] Semi-gloss

Semi-gloss is more commonly used for trimmings such as baseboards, mouldings and doors rather than walls. It offers a hard finish, is easily cleanable, and is suitable for heavy use. The shine is less than full gloss, but a single coat is usually sufficient for a good covering.

[edit] Gloss

This is commonly used on woodwork and metal as it provides a high shine. However, gloss paint tends to show imperfections and often requires several coats.

[edit] Related articles on Designing Buildings

- Acrylic.

- Construction materials.

- Cool paint.

- Decoration.

- Distemper.

- Finishes.

- Fresco.

- How to paint walls in eight steps.

- Interior designer.

- Large-scale murals.

- Lead in construction.

- Limewash.

- Paints and coatings.

- Plastic.

- Plastic coating market.

- The Anatomy of Colour.

- White spirit.

[edit] External references

- Essential Chemical Industry - Paint

Featured articles and news

Delayed, derailed and devalued

How the UK’s planning crisis is undermining British manufacturing.

How much does it cost to build a house?

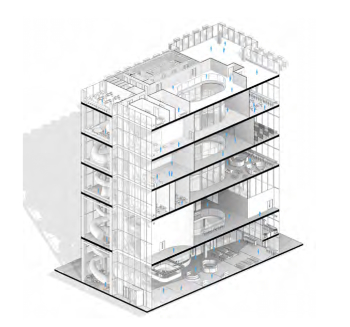

A brief run down of key considerations from a London based practice.

The need for a National construction careers campaign

Highlighted by CIOB to cut unemployment, reduce skills gap and deliver on housing and infrastructure ambitions.

AI-Driven automation; reducing time, enhancing compliance

Sustainability; not just compliance but rethinking design, material selection, and the supply chains to support them.

Climate Resilience and Adaptation In the Built Environment

New CIOB Technical Information Sheet by Colin Booth, Professor of Smart and Sustainable Infrastructure.

Turning Enquiries into Profitable Construction Projects

Founder of Develop Coaching and author of Building Your Future; Greg Wilkes shares his insights.

IHBC Signpost: Poetry from concrete

Scotland’s fascinating historic concrete and brutalist architecture with the Engine Shed.

Demonstrating that apprenticeships work for business, people and Scotland’s economy.

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.