Cast-in-place concrete

Cast-in-place concrete, also known as poured-in-place, is a concreting technique which is undertaken in situ or in the concrete component’s finished position. Cast-in-place concrete is the preferred choice for concrete slabs and foundations, as well as components such as beams, columns, walls, roofs, and so on.

The concrete is typically transported to site in an unhardened state, often using a ready mixed concrete truck. A chute extends from the back of the truck to place the concrete either in the required location or into a dumper or pump.

An alternative concreting technique is precast concrete which is prepared, cast and cured off-site, usually in a controlled factory environment, using reusable moulds. For more information, see Precast concrete.

While cast-in-place concrete can allow for greater flexibility and adaptability, it can be difficult to control the mix particularly if weather conditions are not favourable. Cast-in-place concrete will also require a strength test and time for curing, which makes it slower to construct than precast concrete. However, there are fewer joints in the structural system not as much handling equipment is required.

[edit] Related articles on Designing Buildings Wiki

- Accessories cast into in situ concrete.

- Concrete.

- Concrete slabs.

- Concrete batching plants.

- Concreting plant.

- Curing.

- Floor slab.

- Floor void.

- Mass concrete.

- Precast concrete.

- Prestressed concrete.

- Raft foundation.

- Reinforced concrete.

- Smart concrete.

- Strip foundation.

- Tilt up construction.

- Tremie.

- Types of concrete.

Featured articles and news

Insights of how to attract more young people to construction

Results from CIOB survey of 16-24 year olds and parents.

Focussing on the practical implementation of electrification.

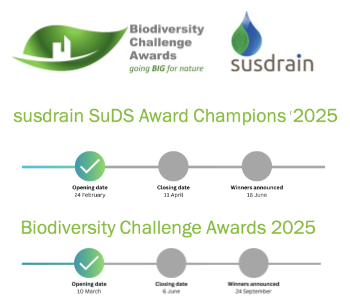

Sustainable Urban Drainage and Biodiversity

Awards for champions of these interconnected fields now open.

Microcosm of biodiversity in balconies and containers

Minor design adaptations for considerable biodiversity benefit.

CIOB student competitive construction challenge Ireland

Inspiring a new wave of Irish construction professionals.

Challenges of the net zero transition in Scotland

Skills shortage and ageing workforce hampering Scottish transition to net zero.

Private rental sector, living standards and fuel poverty

Report from the NRH in partnership with Impact on Urban Health.

.Cold chain condensing units market update

Tracking the evolution of commercial refrigeration unit markets.

Attending a conservation training course, personal account

The benefits of further learning for professsionals.

Restoring Alexander Pope's grotto

The only surviving part of his villa in Twickenham.

International Women's Day 8 March, 2025

Accelerating Action for For ALL Women and Girls: Rights. Equality. Empowerment.

Lack of construction careers advice threatens housing targets

CIOB warning on Government plans to accelerate housebuilding and development.

Shelter from the storm in Ukraine

Ukraine’s architects paving the path to recovery.

BSRIA market intelligence division key appointment

Lisa Wiltshire to lead rapidly growing Market Intelligence division.

A blueprint for construction’s sustainability efforts

Practical steps to achieve the United Nations Sustainable Development Goals.

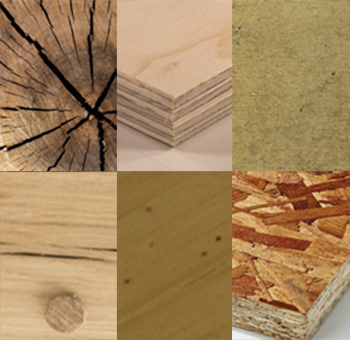

Timber in Construction Roadmap

Ambitious plans from the Government to increase the use of timber in construction.

ECA digital series unveils road to net-zero.

Retrofit and Decarbonisation framework N9 launched

Aligned with LHCPG social value strategy and the Gold Standard.

Comments

"Cast-in-place concrete," also known as "cast-in-situ concrete," refers to a construction method in which concrete is mixed on-site and poured into molds or formwork to create a desired shape or structure. This method is commonly used in various construction projects and offers flexibility, customization, and durability. Here's an overview of cast-in-place concrete:

1. **Formwork Preparation**: Formwork, which can be made from wood, steel, or other materials, is set up to create the desired shape and structure of the concrete element. The formwork serves as a mold that contains the fresh concrete until it hardens.

2. **Concrete Mixing**: Concrete is typically mixed on-site using cement, aggregates (such as sand and gravel), water, and sometimes additives. The concrete mixture's composition is adjusted to meet the structural and design requirements of the project.

3. **Pouring and Placing**: The mixed concrete is poured into the prepared formwork. It's then distributed and compacted using techniques like vibration to eliminate air bubbles and ensure uniformity.

4. **Curing**: After pouring, the concrete needs time to harden and gain strength. Adequate curing methods are applied to maintain moisture and temperature conditions that facilitate proper hydration and strength development.

5. **Finishing**: Once the concrete has sufficiently hardened but is not fully set, finishing techniques like troweling, brushing, or stamping can be used to achieve the desired surface texture and appearance.

6. **Removal of Formwork**: After the concrete has fully cured and gained sufficient strength, the formwork is carefully removed. This reveals the finished concrete structure.

1. **Customization**: Cast-in-place concrete allows for customization of shapes, sizes, and designs to meet specific project requirements.

2. **Structural Integrity**: This method provides strong and durable structures with excellent load-bearing capacity.

3. **Flexibility**: Changes can be made to the formwork or concrete mix during construction to accommodate unexpected design modifications.

4. **On-Site Mixing**: Concrete is mixed on-site, reducing the need for transportation and potential quality issues associated with precast concrete.

5. **Less Transportation**: The raw materials (cement, aggregates) are transported to the site, reducing transportation costs and environmental impact compared to transporting precast elements.

6. **Suitable for Complex Structures**: Cast-in-place concrete is well-suited for complex architectural designs and irregular shapes.

1. **Time-Consuming**: Cast-in-place concrete can take longer to complete compared to using precast elements since the curing process needs to occur on-site.

2. **Labor Intensive**: The process requires skilled labor for concrete mixing, formwork installation, and proper finishing.

3. **Weather Conditions**: Weather can impact the casting process, especially in extreme conditions like rain or freezing temperatures.

4. **Quality Control**: Ensuring consistent quality requires proper concrete mixing, placement, and curing practices.

Cast-in-place concrete is a versatile construction method used for a wide range of structures, from buildings and bridges to infrastructure elements like retaining walls and foundations. The choice between cast-in-place and precast concrete depends on factors such as project scope, design complexity, timeline, and site conditions.