Minimum efficiency reporting value MERV

Contents |

[edit] Introduction

The minimum efficiency reporting value (MERV) can be used to evaluate the effectiveness of air filters in heating, ventilation and air conditioning (HVAC) components.

[edit] Background

The rating system was developed in the 1980s by the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE). ASHRAE develops standards related to refrigeration processes and the design and maintenance of indoor environments. The purpose of the organisation's standards is to establish consensus for test use in commerce as well as performance criteria for use as facilitators.

This MERV rating system is used in the US for comparing air filters made by different manufacturers. It assigns a single number air filter designation based on how well it captures and holds dust. MERV rated filters may be used in place of high efficiency particulate arrestance (HEPA) or ultra low particulate air (ULPA) filters in certain circumstances (such as when central air conditioning systems are in place).

[edit] MERV testing

The MERV rating system is based on ASHRAE Standard 52.2-2007, the testing protocol for air filtration performance.

It reflects a measurement of the filter’s arrestance - or its ability to remove dust from the air - relative to how many of a specific size dust particle (within the range of 0.3 to 10 micrometers) need to be removed to keep HVAC equipment clean.

The test extends over six cycles and begins with a clean filter. During each cycle, a measured amount of particles (broken down into three size categories) is released into the test airstream. These three arrestances are:

- E1 for small particles such as tobacco smoke and bacteria.

- E2 for medium size particles such as welding fumes.

- E3 for larger particles such as dirt, lint, hair and dust.

The number of particles trapped and missed is measured. This procedure is repeated five additional times and the MERV rating is calculated based on the poorest performance rating during the six tests.

The MERV number corresponds to the filter’s efficiency in its clean, least efficient state (which is why the rating is referred to as ‘minimum efficiency’). A filter increases in efficiency as it loads.

[edit] Explanation of ratings

MERV values range from 1 (minimal filtering) to 16 (maximum filtering).

Mid-range rated filters (from 7 to 13) are typically recommended for commercial buildings. During the new construction phase, MERV 8 filters may be advisable, with MERV 13 filters generally recommended once the building is operational.

|

(NB: MERV 17-20 ratings are no longer acknowledged by ASHRAE.) |

Sample rating ranges include:

- MERV 1 to 4. These filters are made from materials such as fibreglass and aluminium mesh. They can be used to remove large particles and protect equipment. They can remove substances such as pollen, dust mites, cockroach debris and carpet fibres and are suitable for light industrial and some residential applications including residential window air conditioning units.

- MERV 5 to 8. These are disposable filters that can be used to remove substances such as mould spores, pet dander and other particulate material commonly found in residential environments and some light industrial and commercial environments.

- MERV 9 to 12. These are higher quality filters used to remove fine household dust particles (such as flour), and Legionella as well as some particles found in workshop fumes. These can be used in more demanding residential, commercial and healthcare environments.

- MERV 13 to 16. These are designed for high levels of filtration for substances such as bacteria, smoke dust and other extremely fine particles. They are suitable for commercial and healthcare applications with extreme filtration requirements. These filters are not suitable for residential HVAC applications or furnaces.

Originally, MERV values ranged from 1 to 20, but ASHRAE stopped recognising MERV values from 17 to 20 in January 2009. This range is instead represented by HEPA and ULPA filters, which are capable of removing extremely high levels of dust particles as well as some viruses and other dangerous airborne particulates.

[edit] The impact of air resistance on MERV

In a furnace or air handler, the queuing up of air to pass through a high-MERV filter creates resistance. Referred to in HVAC language as a pressure drop, this condition decreases airflow on the downstream side of the air filter.

Pressure drop may increase as the MERV number increases. As contaminants load on the filter, pressure in the system rises and can have a negative impact on airflow. This may cause systems to operate for longer periods of time in order to reach certain temperature settings. In extreme cases, decreased airflow over the part of the system that heats (in winter) or cools (in summer) can lead to overheating and an automated system shutdown or icing over of the coil.

[edit] Related articles on Designing Buildings

- Air filtration.

- Air pressure drop APD.

- Arrestance.

- At a glance - Indoor air quality.

- Building ventilation and COVID-19 transmission risk.

- Clean air delivery rate CADR

- Clean indoor air for healthy living - New air filter standards.

- Designing HVAC to resist harmful microorganisms.

- Growing focus on IAQ challenges for specifiers and HVAC manufacturers.

- High efficiency particulate arrestance HEPA.

- HVAC.

- Indoor air quality.

- Mechanical ventilation of buildings.

Featured articles and news

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

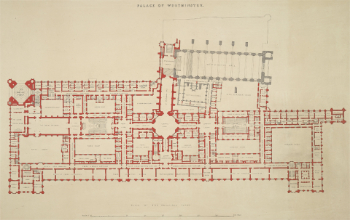

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.