Laminated glass

Contents |

[edit] Introduction

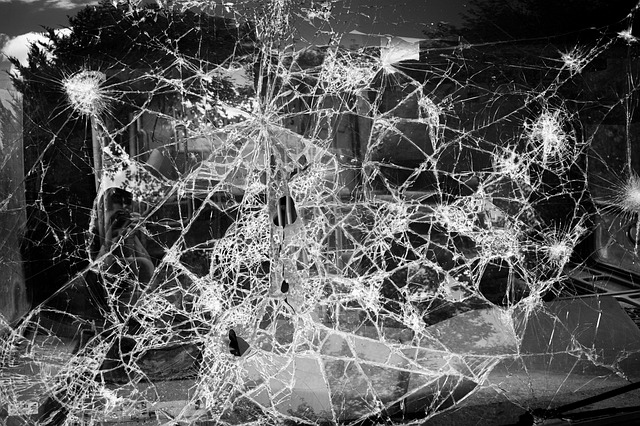

Laminated glass (sometimes called toughened laminated glass) comprises two or more layers of glass sandwiched together with tear-resistant plastic film interlayers (usually polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA). The aim is to create a glass composite which can absorb the energy of a person or object that strikes it, preventing penetration of the pane and potential injuries that might result from flying fragments of broken glass.

An additional benefit of laminated glass is that most ultraviolet radiation can be blocked by the PVB or EVA interlayer. Thermoset EVA layers can block up to 99.9% of UV rays.

[edit] Applications

Laminated glass can be used for safety or security reasons. It is used for architectural applications where for example, the glass could fall from a height and shatter, and also for roof, balcony and terrace balustrading, as well as for skylights. It can also be used as a decorative material due to the wide variety of interlayers available, e.g coloured, textured, meshed or patterned. It is particularly useful for windows and shopfronts in areas prone to hurricanes.

In addition to flat sheets, it can be supplied in curved sections, as may be required for car windscreens.

[edit] Manufacture

Bonding together the alternating layers of, typically annealed glass, and plastic film is usually achieved through the use of heat and pressure created by an autoclave.

Manufacture can involve using heat-strengthened glass, which, when it breaks, does so into large pieces held in the frame by the PVB inter-layer. Or it can be made from tempered glass, where the sheet may fall out of the frame but will mostly stay together due to the interlayer.

Digital printing for special effects can be created by printing on to the glass prior to laminating or printing onto the interlayer.

[edit] Configurations

Laminated glass is available in various thicknesses and configurations. A typical glass-layers configuration can comprise 2.5mm glass – 0.38mm interlayer – 2.5mm glass, resulting in ‘5.38 laminated glass’.

Thicker glass and multiple laminates giver a stronger product. Thicker configurations such as double– or triple-laminate with interlayers (int) can include the following:

[edit] Double laminate:

- 6mm - int - 6mm.

- 8mm - int - 8mm.

- 10mm - int - 10mm.

[edit] Triple laminate:

- 6mm - int - 6mm - int -6mm.

- 8mm - int - 8mm - int -8mm.

- 10mm - int - 10mm - int -10mm.

The cockpit of an aircraft such as a Boeing 747 may include a triple-laminated glass construction comprising three layers of 4mm toughened glass with 2.6mm PVB layers in between, making a total glass thickness of 17.2mm.

[edit] Related articles on Designing Buildings Wiki

- BFRC window rating scheme.

- BREEAM Visual comfort View out.

- Curved glass.

- Daylit space.

- Domestic windows.

- Double glazing.

- Emissivity.

- Float glass process.

- Glass.

- Low-E glass.

- Overheating.

- Patent glazing.

- Preventing overheating.

- R-value.

- Rights to light.

- Safety glass.

- Secondary glazing.

- Security glazing.

- Structural glass assembly.

- Suction lifter.

- Types of window.

- U-value.

- Window.

Featured articles and news

The history of building regulations

A story of belated action in response to crisis.

Moisture, fire safety and emerging trends in living walls

How wet is your wall?

Current policy explained and newly published consultation by the UK and Welsh Governments.

British architecture 1919–39. Book review.

Conservation of listed prefabs in Moseley.

Energy industry calls for urgent reform.

Heritage staff wellbeing at work survey.

A five minute introduction.

50th Golden anniversary ECA Edmundson apprentice award

Showcasing the very best electrotechnical and engineering services for half a century.

Welsh government consults on HRBs and reg changes

Seeking feedback on a new regulatory regime and a broad range of issues.

CIOB Client Guide (2nd edition) March 2025

Free download covering statutory dutyholder roles under the Building Safety Act and much more.

AI and automation in 3D modelling and spatial design

Can almost half of design development tasks be automated?

Minister quizzed, as responsibility transfers to MHCLG and BSR publishes new building control guidance.

UK environmental regulations reform 2025

Amid wider new approaches to ensure regulators and regulation support growth.

The maintenance challenge of tenements.

BSRIA Statutory Compliance Inspection Checklist

BG80/2025 now significantly updated to include requirements related to important changes in legislation.