What is H-Scaffolding?

Contents |

[edit] What is H-scaffolding?

H-scaffolding is a platform for plastering, painting, insulation, and cladding work on the internal and external walls of buildings, as well as for the construction and repair of ships. It consists of vertical, horizontal, and diagonal sections and is known for its rigidity, reliability, and safety features. The basic elements of H-scaffolding include interconnected frames, metal plates, stairs, base jacks, adjustable supports, and adjustable screws. It is made from certified tubes and is hot-dipped galvanised for durability. H-scaffolding can be used in a variety of settings, including residential and commercial buildings, subway and metro stations, industrial buildings, energy facilities, medical institutions, viaducts and bridges, and hydroelectric projects. It can also be used as staging for higher heights in commercial and industrial buildings and for other architectural purposes. H-frames are made from 40 NB Class B tubes and are an efficient and cost-effective way to erect scaffolding at maximum height with minimum labour and tools. They can be used on their own or in combination to create towers or arrays of the exact height needed for a job.

[edit] Basic elements

The system basically consists of interconnected frames. One H-frame is 2 metres high, while the length between two H-frames is 2.5 metres. The system also uses auxiliary elements.

Adjustable screws are used to eliminate the height difference of inclined floors. Steel working platforms add strength and safety to the scaffolding. Access between floors is safe within the scaffold, in certain applications such as stairs or access ladders. The use of scaffold clamps in sheathing work ensures the safety of the scaffold and makes it easier to use.

[edit] Features of H-frame scaffolding

The system is made from TS EN 10219-1 certified tubes, 48.3 × 3.0mm frames, 42 × 2.5mm diagonal elements and 34 × 2.0mm horizontal elements. The production of our scaffolding is carried out by means of gas welding robots in accordance with the EN ISO 3834-3 welding quality standard.

The working platform has a load capacity of 300 kg / m² and is manufactured by means of a roll forming machine. The system is hot-dipped galvanised in accordance with TS EN 12811-2.

[edit] Related articles on Designing Buildings

- Building wraps.

- Debris netting.

- Demolition.

- Facade retention.

- Falsework.

- Formwork.

- Gantry.

- How to remove scaffolding.

- How to use a ladder.

- Putlog holes.

- Roped access for conservation projects.

- Rubble chute.

- Scaffold.

- Scaffold register.

- Shoring.

- Temporary works.

- Trench support.

- Types of crane.

- Types of scaffolding.

- Work at height.

- Work at height checklist for managers.

- Work at height regulations.

- Working platform.

Featured articles and news

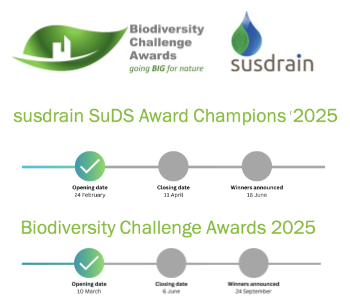

Sustainable Urban Drainage and Biodiversity

Awards for champions of these interconnected fields now open.

Microcosm of biodiversity in balconies and containers

How minor design adaptations for considerable biodiversity benefit.

CIOB student competitive construction challenge Ireland

Inspiring a new wave of Irish construction professionals.

Challenges of the net zero transition in Scotland

Skills shortage and ageing workforce hampering Scottish transition to net zero.

Private rental sector, living standards and fuel poverty

Report from the NRH in partnership with Impact on Urban Health.

.Cold chain condensing units market update

Tracking the evolution of commercial refrigeration unit markets.

Attending a conservation training course, personal account

The benefits of further learning for professsionals.

Restoring Alexander Pope's grotto

The only surviving part of his villa in Twickenham.

International Women's Day 8 March, 2025

Accelerating Action for For ALL Women and Girls: Rights. Equality. Empowerment.

Lack of construction careers advice threatens housing targets

CIOB warning on Government plans to accelerate housebuilding and development.

Shelter from the storm in Ukraine

Ukraine’s architects paving the path to recovery.

BSRIA market intelligence division key appointment

Lisa Wiltshire to lead rapidly growing Market Intelligence division.

A blueprint for construction’s sustainability efforts

Practical steps to achieve the United Nations Sustainable Development Goals.

Timber in Construction Roadmap

Ambitious plans from the Government to increase the use of timber in construction.

ECA digital series unveils road to net-zero.

Retrofit and Decarbonisation framework N9 launched

Aligned with LHCPG social value strategy and the Gold Standard.

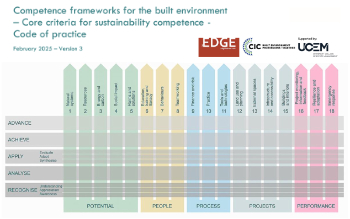

Competence framework for sustainability

In the built environment launched by CIC and the Edge.

Institute of Roofing members welcomed into CIOB

IoR members transition to CIOB membership based on individual expertise and qualifications.

Join the Building Safety Linkedin group to stay up-to-date and join the debate.

Government responds to the final Grenfell Inquiry report

A with a brief summary with reactions to their response.

Comments

[edit] To make a comment about this article, click 'Add a comment' above. Separate your comments from any existing comments by inserting a horizontal line.