Electric motors in the built environment

An electric motor is a machine that converts electrical energy into mechanical energy. Often the mechanical energy will be in the form of rotational energy.

Electric motors producing a rotary force (torque) or sometimes linear force, are distinguished from devices such as solenoids or loudspeakers which do not generate a useable mechanical force. These latter devices are referred to as actuators or transducers.

The basic principle of all motors is the use of an electric current flowing through a wire winding to create a magnetic field, which interacts with another magnetic field to generate a force in the form of rotational or linear movement energy.

The magnetic fields follow the basic principle that like fields repel and unlike fields attract, to create a mechanical force.

Electrical motors in building applications may range in size from small devices consuming typically less than 1 Watt, such as may be found in a small clock or timer, to several hundred kilowatts, such as may be encountered in large scale mechanical services installations which may perform fluid pumping, air movement or compressor-driven refrigeration duties.

Most motors used within building applications operate on alternating mains current (AC) and are of the induction motor type. These motors are smaller in size, and usually range in power from about 50 Watts up to several kilowatts. They may run on a single-phase mains supply.

Larger motors, ranging from a few kilowatts in size up to several hundred kilowatts, more usually have a three-phase mains supply.

Traditionally, the speed of AC induction motors was governed by the mains supply frequency, which in the UK is 50Hz. Any speed variation to the driven load thus had to be undertaken via a process of mechanical reduction gearing usually via belts and pulleys, or mechanical gearboxes.

With the advent of high-power electronics and the ability to alter the frequency of the mains supply, many AC induction motors are now capable of being driven at a range of speeds, by use of variable speed drives (VSDs). Such speed variation is often used to give precise control to processes such as pumping or air movement and is most often employed to increase energy efficiency.

Other types of motor sometimes encountered in buildings may include:

- AC brushed type, where carbon brushes pass electricity from the stationary part of the motor (stator) to the rotating part (rotor) via a rotating set of slip-ring segments known as a commutator. These are often encountered in smaller items of equipment and electrical appliances such as vacuum cleaners and power tools, where a high starting toque and fast speed run up are needed.

- Direct current motors – usually employing carbon brushes and commuter. These are less common but may be encountered in some electrical appliances, particular those designed to be run from portable DC sources such as batteries.

- Stepper motors – these are used where precise rotation, often a few degrees at a time may be required, such as in some electromechnical switching or process control systems.

- Servo motors – similar to stepper motors but often used in connection with position or speed control feedback, and may be encountered in some machine tools, plotters, etc.

- Linear motors – this does not produce a twisting force (torque) but instead produces a straight-line force along its length. They may be encountered in some forms of horizontal transportation systems or specialist industrial processes.

--ECA

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

Managing building safety risks

Across an existing residential portfolio, a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

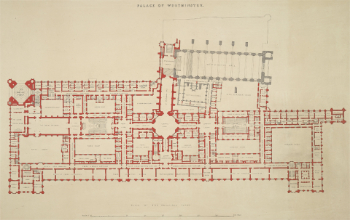

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.