Value management in building design and construction

Contents |

[edit] History of development

Value Management (VM) and Value Engineering (VE) are techniques concerned with defining, maximising and achieving 'value for money' (VfM). These are systematic team-based collaborative approaches, initially pioneered in the United States during the Second World War to secure maximum output from limited resources.

At the initial stages of a project, value management provides an exceptionally powerful tool to explore a project’s objectives and aspirations from the client’s perspective.

Whilst the process originated in the manufacturing industry, the key initiating question (“what function does a component perform and how else can this function be performed”) is equally applicable to a wide range of disciplines, including construction, and within 10 years of the concept emerging, the US Department of Defence incorporated VfM into the delivery of its very extensive construction programme.

Although its use was widespread in the US from the 1950’s, it took another three decades for the concept to be applied in Europe, with the first application in the UK in 1983 by the American company Xerox. One of the reasons for this slow uptake was due to the fact that the US approach to VfM required a separate team to audit the incumbent design team’s proposals. The design team was then expected to implement the audit team’s proposals. This predictably opened up problems relating to design responsibility, legal complications and even professional rivalry.

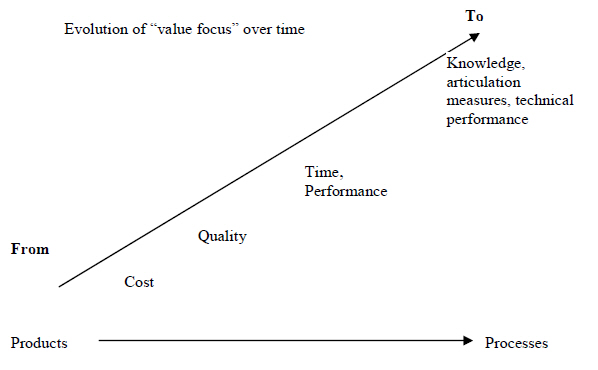

However, with the growing spread of the quality movement in the 1980’s and the shift of the initial focus from materials to cost and quality, the concept was eventually accepted in the UK and Europe, where the design team became a key part of the team undertaking the value audit.

With time, there was a realisation that materials, cost and quality, as governed by the specification, were not enough. Products had to respond to the needs of the customer. Emphasis therefore shifted to a more rounded appreciation of value, encapsulating cost, time, performance, knowledge and technical competency.

At the same time, the scope of the studies also grew, to capture processes as well as products, with a focus on expressing and measuring value in such a way that the project team can respond with the most effective solutions.

A key differentiator between the value management concept and many other processes is that value management focuses on the expected outcome of a project. Only once the outcome is clearly established, understood, agreed and defined, does the process address the question of how it will be delivered.

The outcomes are represented in a statement of project objectives, expressed in terms of the expected benefits to the business. These are linked through 'value drivers' (defined as a functional attribute that is necessary to fully deliver the expected benefits from a project – equivalent to a primary function) to the design intent. Later, as the project evolves, these relate directly to the design solutions and what is built.

[edit] The need for value management on construction projects

Construction projects have been the subject of frequent reviews and reports. A significant number of these, including the Emerson report (1962), the Banwell report (1963), the Wood report (1975), Latham reports (1993, 1994) and the Egan report (1998) identified recurring themes:

- The adversarial nature of operation and contractual relationships.

- A need for integration of the supply chain.

- A need for simplicity in contractual language and arrangements.

- A need to move away from the cheapest option towards the ‘best value’ option.

From this it is evident that the principles and methodology of value management are not only necessary in construction projects to achieve better value from the resources, but also to deliver ancillary benefits such as better communication, improved team-working, better alignment of the supply chain and a better understanding of project objectives.

The application of value management in construction projects will largely depend on the value of a particular project and the level of the risks involved. The figure below indicates a typical risk and value matrix which can be used to identify the need and necessity of value management.

[Image: Risk & Value Matrix (Based on the Kraljic matrix for supplier positioning).]

For strategic – critical projects (high risk, high value), a full value management process is almost always justified. For strategic – security projects (high risk, low value) and tactical – profit (low risk, high value) projects, the necessity of value management will depend upon the merits of each project. For tactical – acquisition projects (low risk, low value) a value management exercise may not be necessary.

The primary benefits of a value management exercise are:

- A clear definition of what the owners and end users mean by value, thus providing a precise basis for making decisions throughout the project.

- A tool for optimising the balance between differing stakeholder needs and expectations.

- A basis for creating a clear project brief that reflects the project sponsor’s priorities and expectations, expressed on the basis of value and function. This improves communication between all the stakeholders so that each can understand and respect the other’s constraints, expectations and requirements.

- A basis for ensuring the project is the most effective way of delivering business benefits and satisfying business needs.

- A functional basis for embellishing and refining the business case for the project, by addressing both the monetary and non-monetary benefits.

- A functional basis for design development and management, through improved communications, mutual learning and enhanced collaborative working, leading to better technical solutions with enhanced performance and quality, often through innovative solutions.

- A functional mechanism to measure value, taking into account monetary and non-monetary benefits and thus demonstrating value for money.

Value management can be a very low-cost, high-benefit exercise. When integrated into the project management methodology early in the project life cycle, the cost may become almost negligible because of the reduced need for subsequent reviews and opportunities for substituting value management for some of the routine appraisals and quality audits that are always necessary.

The benefits of a value management review are often perceived in terms of improved quality and reduced cost. However the 'invisible' benefits can be just as, or more valuable. Consensus and mutual understanding between stakeholders, clear objectives, reduced risk of changes in scope and improved communications will help ensure that the project meets the objectives of the client and is delivered within the relevant parameters.

[edit] Process

Value management is a team-based approach used to define the client's objectives and ensure best value, whole-life solutions are selected to satisfy those objectives. It is not necessarily about cost cutting.

To achieve maximum benefit, value management should be carried out from the very early stages of a project, not simply introduced when problems occur. The process of value management includes value engineering, which is a more systematic approach to ensuring specific functions are satisfied to the required standard for the least cost. It assess a range of possible solutions against the values required by the client.

Value management exercises can also be used to recover cost divergence (costs diverging from the budget) that may become apparent when design reports are prepared. Under these circumstances, the client may have to choose priorities, or decide to increase the budget.

It may be possible to:

- Identify items that can be omitted.

- Identify items that can have their specification changed.

- Identify items that could be re-instigated later in the programme if the budget allows.

- Identify enabling works that can be incorporated into the design, allowing elements to be added during later phases of construction.

The client and the full consultant team should take part, along with the contractor, construction manager or management contractor if appointed.

[edit] Techniques

There are a number of techniques which are commonly used in the conduct of VM studies. Some of these techniques are:

- Function analysis.

- Function analysis system technique (FAST).

- Cost/worth.

- SMART methodology.

- Value drivers.

- Value benchmarking (or value profiling).

- Options selection.

- Weighting techniques.

- Creative techniques.

- Evaluation techniques.

- Scenarios technique.

- Target costing.

- Function performance specification (FPS).

For more information, see Value management techniques.

See also Overcoming difficulties in value management.

This article has been developed based on VALUE MANAGEMENT IN CONSTRUCTION, by Saleem Akram, Andrzej Minasowicz, Bartosz Kostrzewa, Arnab Mukherjee and Piotr Nowak. The original manual was published in 2011. It was developed within the scope of the LdV program, project number: 2009-1-PL1-LEO05-05016 entitled “Common Learning Outcomes for European Managers in Construction”.

It is reproduced here in a slightly modified form with the kind permission of the Chartered Institute of Building.

--CIOB

[edit] Related articles on Designing Buildings Wiki

- Best value.

- Budget.

- Code of practice for programme management.

- Constraints.

- Construction industry reports.

- Cost exercises.

- Cost plans.

- Existing use value.

- Lean construction.

- Lean construction - a quality perspective.

- Market value.

- Pareto analysis.

- Overcoming difficulties in value management.

- Quality in construction projects.

- Value added.

- Value engineering.

- Value management techniques.

- Value planning.

- Whole life costs.

- Whole-life value.

[edit] External references

- OGC Achieving Excellence Guide 4: Risk and Value Management.

- RICS draft guidance note: Managing the design delivery.

- RICS draft guidance note - Value engineering and value management - for models of application of value management/value engineering within differing procurement routes.

- Value Management in Construction, CIRIA SP129, 2006 A Client's Guide, John N. Connaughton, S.D. Green

- Kelly, J; Male, S and D Graham (2004) Value Management of Construction Projects, Blackwell Science

Featured articles and news

Homes England creates largest housing-led site in the North

Successful, 34 hectare land acquisition with the residential allocation now completed.

Scottish apprenticeship training proposals

General support although better accountability and transparency is sought.

The history of building regulations

A story of belated action in response to crisis.

Moisture, fire safety and emerging trends in living walls

How wet is your wall?

Current policy explained and newly published consultation by the UK and Welsh Governments.

British architecture 1919–39. Book review.

Conservation of listed prefabs in Moseley.

Energy industry calls for urgent reform.

Heritage staff wellbeing at work survey.

A five minute introduction.

50th Golden anniversary ECA Edmundson apprentice award

Showcasing the very best electrotechnical and engineering services for half a century.

Welsh government consults on HRBs and reg changes

Seeking feedback on a new regulatory regime and a broad range of issues.

CIOB Client Guide (2nd edition) March 2025

Free download covering statutory dutyholder roles under the Building Safety Act and much more.

Minister quizzed, as responsibility transfers to MHCLG and BSR publishes new building control guidance.

UK environmental regulations reform 2025

Amid wider new approaches to ensure regulators and regulation support growth.

BSRIA Statutory Compliance Inspection Checklist

BG80/2025 now significantly updated to include requirements related to important changes in legislation.

Comments

To start a discussion about this article, click 'Add a comment' above and add your thoughts to this discussion page.