Synthetic gypsum

Synthetic gypsum is a term used to describe a number of gypsum based products than can be used as a alternative to or in conjunction with natural gypsum.

There are a number of different processes involved with the production of synthetic gyspum and different terms to decribe these;

- Flue Gas Desulphurisation (FGD) gypsum is a by-product of the wet purification procedure with natural lime, formed in scrubbing towers of power plants, a extremely sped up process, similar to that of forming natural Gypsum. The SO2 is washed out by water, oxidised to Sulphates SO3 in an aqueous solution, calcium from quicklime precipitates into a purer form (than natural) of gypsum, Dihydrous Calcium Sulphate (CaSO4,2H2O). It is the most common process to create synthetic gypsum.

- Phosphogypsum, is based on reaction with phosphoric acid, a commodity chemical used in the production of fertilisers and detergents which also produces Calcium Sulphate, which can be separated filtration. It can be problematic in terms of crystal shape, quality and riskss of natural radioactivity,

- Titanogypsum, half the production of Titanium Dioxide (a mass produced white pigment) comes from a sulphate, (the other by a chloride) process, of around half produces a white gypsum which can be used.

- Citrogypsum, is a by product in the processing of citric acid, normally blueish in colour by can be purified.

- Fluoroanhydrite, calcium sulphate can form in the production of hydrofluoric acid from heated fluorspar or fluorite with Sulphuric Acid in dry conditions.

- Other synthesised gypsums have potential to be formed by processes with a by-product of sulphuric acid, whilst similar to citrogypsum and citric acid, tartaric, lactic, formic and oxalic acid also produce gypsum.

In 2007 the European gypsum industry organisation (EuroGypsum) stated that;

"Natural Gypsum will continue to cover the basic raw material needs of the Gypsum industry, followed by FGD Gypsum. The most important potential of other synthetic Gypsums than FGD Gypsum lies in the use of purified Phosphogypsum. Next to that is some potential in the use of purified Titanogypsum. In the past, both the Phosphoric Acid and the Titanium Dioxide industries have shown a systematic close down of production facilities in Europe. Investments in either the purification of the produced Gypsums, or in finding applications for the Gypsums produced, may be essential for the future viability of these sites."

[edit] Related articles on Designing Buildings

Featured articles and news

Spring Statement 2025 with reactions from industry

Confirming previously announced funding, and welfare changes amid adjusted growth forecast.

Scottish Government responds to Grenfell report

As fund for unsafe cladding assessments is launched.

CLC and BSR process map for HRB approvals

One of the initial outputs of their weekly BSR meetings.

Architects Academy at an insulation manufacturing facility

Programme of technical engagement for aspiring designers.

Building Safety Levy technical consultation response

Details of the planned levy now due in 2026.

Great British Energy install solar on school and NHS sites

200 schools and 200 NHS sites to get solar systems, as first project of the newly formed government initiative.

600 million for 60,000 more skilled construction workers

Announced by Treasury ahead of the Spring Statement.

The restoration of the novelist’s birthplace in Eastwood.

Life Critical Fire Safety External Wall System LCFS EWS

Breaking down what is meant by this now often used term.

PAC report on the Remediation of Dangerous Cladding

Recommendations on workforce, transparency, support, insurance, funding, fraud and mismanagement.

New towns, expanded settlements and housing delivery

Modular inquiry asks if new towns and expanded settlements are an effective means of delivering housing.

Building Engineering Business Survey Q1 2025

Survey shows growth remains flat as skill shortages and volatile pricing persist.

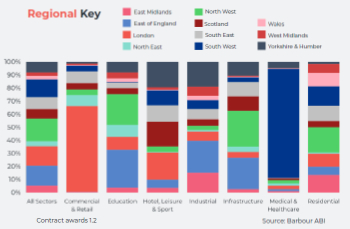

Construction contract awards remain buoyant

Infrastructure up but residential struggles.

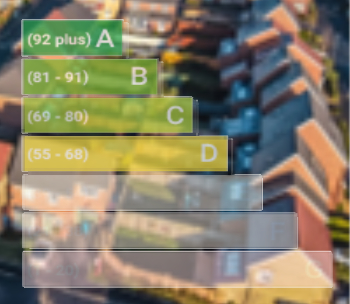

Warm Homes Plan and existing energy bill support policies

Breaking down what existing policies are and what they do.

A dynamic brand built for impact stitched into BSRIA’s building fabric.