Resource allocation in design and construction

Contents |

[edit] Introduction

Resource allocation is a business term that describes the assignment of people, materials, plant and other resources to specific projects, tasks or other uses. In design and construction terms, resource allocation can be used to describe the process of assigning people, materials, tasks and so on based on availability and scheduling requirements.

Also see Resource management.

[edit] Proper resource allocation

It is important to determine if the correct number and mix of people are available to be able to deliver the work that has been accepted. Having adequate resources in place to provide clients with a professional service is a requirement of both the ARB and RIBA codes.

Problems with projects can occur where there is poor resource allocation. These difficulties have become more prevalent as buildings have become more technical, the range of products and materials has increased, standards and regulations have become more strict, and there are a greater number of specialist designers, particularly in the early stages of the design process.

To reduce these issues, resource allocation should be pre-planned and, where appropriate, allocated to the specific tasks. Properly scheduling the available resources is crucial in ensuring that the project proceeds correctly and within the established timeframe and budget.

If resources are limited, this can sometimes result in conflicts that can be addressed using allocation methods. Allocation ensures that the resources required do not exceed those available, but on the condition that any resulting delay is kept to a minimum.

Also see Resource leveling.

[edit] Algorithms for resource allocation

Practical problem solving approaches such as the Wiest-Levy method for resource allocation are commonly used and can provide good solutions relatively quickly.

The Wiest-Levy method is based on the scheduling of activities which can be carried out using the resources available. When the load is greater than the available resource, the activity will have to be delayed; amongst the most non-critical activities, the one that solves the problem with the least delay is chosen. If there are two activities with the same conditions, the one with the greatest float is delayed first, meaning that critical activities are only delayed when there is no other option.

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

Government responds to the final Grenfell Inquiry report

A with a brief summary with reactions to their response.

A brief description and background to this new February law.

Everything you need to know about building conservation and the historic environment.

NFCC publishes Industry White Paper on Remediation

Calling for a coordinated approach and cross-departmental Construction Skills Strategy to manage workforce development.

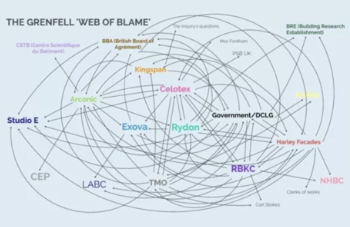

'who blames whom and for what, and there are three reasons for doing that: legal , cultural and moral"

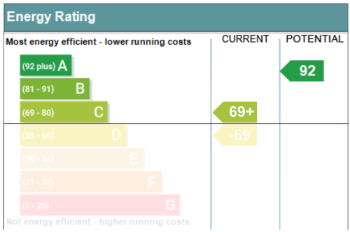

How the Home Energy Model will be different from SAP

Comparing different building energy models.

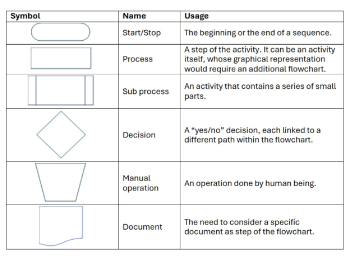

Mapping approaches for standardisation.

UK Construction contract spending up at the start of 2025

New construction orders increase by 69 percent on December.

Preparing for the future: how specifiers can lead the way

As the construction industry prepares for the updated home and building efficiency standards.

Embodied Carbon in the Built Environment

A practical guide for built environment professionals.

Updating the minimum energy efficiency standards

Background and key points to the current consultation.

Heritage building skills and live-site training.

Shortage of high-quality data threatening the AI boom

And other fundamental issues highlighted by the Open Data Institute.

Data centres top the list of growth opportunities

In robust, yet heterogenous world BACS market.

Increased funding for BSR announced

Within plans for next generation of new towns.