Collaboration: a quality management perspective

Contents |

[edit] Summary

This article discusses what collaborative working is intended to achieve, emphasising the basis upon which collaboration can be successfully put in place between partners. It also provides an overview of ISO 44001 and its place in describing the requirements for the arrangements that an organisation should have in place to manage the journey from the decision to become collaborative to the exit from individual collaborative relationships.

[edit] Definition of collaboration

There is no definitive description that can be applied to collaboration in the workplace, even ISO 44001 makes no attempt. The reason for this is that the forms that collaboration can take are so diverse that no one single definition can encompass its wide variety. It is more an attitude towards working one with another that respects and trusts the individual, than a management system

Collaboration can be found in the merger of two organisations into one, in a contractual relationship between a client and one or more contractors or between two persons writing a paper – to mention only three varieties. The common feature is the trust that bonds the parties together.

If I climb a rock face, I place considerable trust in the person at the top of the cliff who holds the rope around my waist. This trust is two-fold, physical capability to secure the rope and the moral strength not to release me to drop onto the rocks below. So it is with working collaboratively within business: each party has compete trust in each of the others, extending to both the capability to successfully complete their element of the works without micro-management and the moral attitude to behave in a responsible, mature manner.

Relationships are delicate. They require quiet resolution of differences, forgiveness for mistakes and sensible, mature approaches that respect persons and avoid emotional outbursts. It is essential that any differences of opinion are resolved as close to the work face as possible without escalation, although ISO 4401 does allow for a Principal in each organisation to act as the final arbitrators where all else fails.

Working relationships need only those persons who are prepared to be collaborative by personality. Top management must be careful in their choice of staff to be certain that the right staff are allocated. There is no point in employing a ‘robust’ expeditor to work within a highly collaborative supply chain.

[edit] ISO 44001: Collaborative business relationship management systems

As is clear from the title of this clause, this standard defines the requirements and framework for management systems for working collaboratively. It is not the place of this article to repeat the standard or any of the other supporting publications from the International Organisation for Standardisation. Equally, a useful explanation of the requirements of the standard can be found in a publication from the Institute for Collaborative Working entitled ‘Insight into ISO 44001’ to which reference should be made.

The standard requires the organisation to determine their internal arrangements for managing collaborative working and then for each of the phases of each individual relationship. It requires that the internal arrangements are defined in such a way as to minimise risk to the success of the relationship and then to define suitable arrangements for each collaborative relationship into which it enters from outset to exit.

[edit] Collaborative relationship management

The first question that any organisation should ask itself is whether or not it intends to work collaboratively and, if so, with whom as a general principle. This is an important decision that is frequently sidelined, as no-one wishes to be thought of as not being collaborative. Here we are talking about entering into formal collaborative relationships that will be managed in accordance with ISO 44001 and not a reflection on the reputation of the organisation. There is no intention at this point to define individual prospective partners, but to identify the profile of suitable organisations with whom they would wish to formally collaborate. This should include a proactive and continuing identification of opportunities where collaborative working will benefit all partners.

Not all relationships within a supply chain are likely to be collaborative. The purchase of services, such as window cleaning or stationery, the sale of a new motor vehicle or the supply of electrical components are most likely to be transactional, that is it will not be necessary to set in place a formal collaborative relationship to achieve the required goal. It is only through a thorough investigation of all opportunities that the organisation can be certain to prosper through collaborative working.

Having decided to act collaboratively, the organisation should decide the boundaries for the collaboration. This might take place between two organisations for the purpose of managing a construction project, for example. It could be, as in the case of some larger projects, to include almost the entire supply chain. In any case, each organisation must develop a management system within itself to define the arrangements it intends to take when entering, continuing and ending a relationship in a ‘Relationship management manual’ or equivalent. From there, it is in a position to plan for each individual relationship.

The main objective of any management system is to militate against risk to its business. In this case, focus is on the potential for risk in collaborating with those classes of organisation identified by profiling. These may arise between the parties from an ‘interested party’. This term ‘interested party’ has significance and should not be limited to the obvious. The organisation should list the parties that have an interest in each individual relationship. This can be difficult, as there may be a different set of interested parties for each collaboration where projects are concerned. It may be profitable for an organisation to define, say, local authorities as an interested party in general in the ‘Relationship management manual’ and then list the specific authorities in ‘Project relationship management plan’. (Note: it is understood that not all organisations will run projects: the term is used to mean the documented arrangements for an individual collaboration).

Within each collaborative relationship, there should be joint management. Consider a large contract that includes tunnelling, laying of rail and signalling. A relationship between these contractors and the client should result in each party having an equal say on a joint management committee with a joint approach to definition of objectives, risk management, value creation and continuity of business following exit from the relationship. It is the intention of the standard that all issues are resolved at the earliest point possible. Hopefully, this will be at the point where they arise. They may be raised to the joint management committee. Each party to the relationship should appoint a ‘Senior executive responsible’ (SER) at director level within their organisation. This person should have sufficient seniority to be able to make decisions that may affect both the project and, potentially, the organisation itself. The role should not be delegated except where unavoidable and only to a person who is not intimately connected to the project. This will enable the SERs to provide direction to the project.

The exit strategy is an important element of planning for collaboration. The exit will happen. This will, hopefully, be when the works have been completed, but may be triggered by circumstances that were not envisaged at the start, such as the takeover of one of the partners. There may also be a disengagement at the end of the design phase with re-engagement with additional partners for the construction phase. Whatever the circumstances, the partners should plan jointly for the exit, including planning for any future work for which they may collaborate.

[edit] ISO 44001

ISO 44001:2017 has been developed from BS 11000. The International Organisation for Standardisation has defined a template for all management standards in its ‘Annex SL’. This is very prescriptive and contains not only the structure, but in most clauses the words that are to be used when developing an international standard. Further information on Annex SL can be found in this article: https://www.designingbuildings.co.uk/wiki/Annex_SL.

While there is good intention in blending the requirements for collaborative working with those of other arrangements within the management system, there are difficulties in doing this for all but the most obvious clauses, such as document control. This is because Annex SL envisages established situations that will only change to improve. They will be fundamentally set down for a structured environment, such as a quality management system, that will improve and update, but will contain a single set of arrangements. ISO 44001 on the other hand describes the journey of a relationship from its initiation to its end. Each relationship will follow its own path, such that, while the pattern will be the same (more or less), the implementation will vary from one project to another.

Some of the requirements for risk assessment and the regular management activities have been pulled into the standard clauses, wherever practicable. The bulk of the requirements for managing relationships is to be found in Clause 8, which is the discipline-centric part of the standard. Those familiar with BS 11000 will recognise much that is there and will appreciate the difficulties that were faced, successfully, in rewriting the British standard into the format of Annex SL.

Readers are recommended to refer to the excellent information provided by the Institute for Collaborative Working in conjunction with that from the International Organisation for Standardisation to widen their experience.

Original article written by Keith Hamlyn, reviewed by Paul Greenwood and accepted by the CWG on 12 December 2018

--ConSIG CWG 15:48, 05 Jan 2019 (BST)

[edit] Related articles on Designing Buildings Wiki:

- Adversarial behaviour in the UK construction industry.

- BS11000.

- Can relationships in and between organisations make tangible differences to business performance?

- Collaborative pracitices.

- Collaborative procurement.

- Cost of quality.

- Digital quality management in construction.

- Egan Report.

- Framework agreement.

- Government Construction Strategy.

- Integrated project delivery (IPD).

- Integrated project team.

- Integrated supply team.

- Integrated systems.

- Latham Report.

- Leadership styles.

- Multi-disciplinary.

- NEC3.

- Partnering.

- PPC 2000.

- Relationship management.

- Supply chain management.

- Team behavioural roles.

- Team management.

Featured articles and news

Insights of how to attract more young people to construction

Results from CIOB survey of 16-24 year olds and parents.

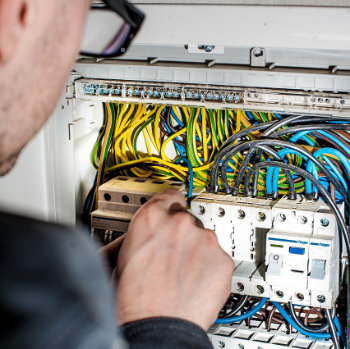

Focussing on the practical implementation of electrification.

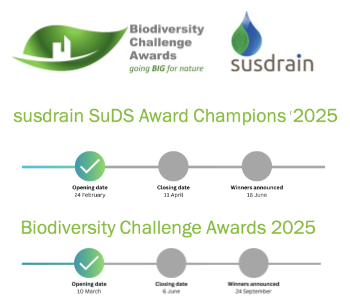

Sustainable Urban Drainage and Biodiversity

Awards for champions of these interconnected fields now open.

Microcosm of biodiversity in balconies and containers

Minor design adaptations for considerable biodiversity benefit.

CIOB student competitive construction challenge Ireland

Inspiring a new wave of Irish construction professionals.

Challenges of the net zero transition in Scotland

Skills shortage and ageing workforce hampering Scottish transition to net zero.

Private rental sector, living standards and fuel poverty

Report from the NRH in partnership with Impact on Urban Health.

.Cold chain condensing units market update

Tracking the evolution of commercial refrigeration unit markets.

Attending a conservation training course, personal account

The benefits of further learning for professsionals.

Restoring Alexander Pope's grotto

The only surviving part of his villa in Twickenham.

International Women's Day 8 March, 2025

Accelerating Action for For ALL Women and Girls: Rights. Equality. Empowerment.

Lack of construction careers advice threatens housing targets

CIOB warning on Government plans to accelerate housebuilding and development.

Shelter from the storm in Ukraine

Ukraine’s architects paving the path to recovery.

BSRIA market intelligence division key appointment

Lisa Wiltshire to lead rapidly growing Market Intelligence division.

A blueprint for construction’s sustainability efforts

Practical steps to achieve the United Nations Sustainable Development Goals.

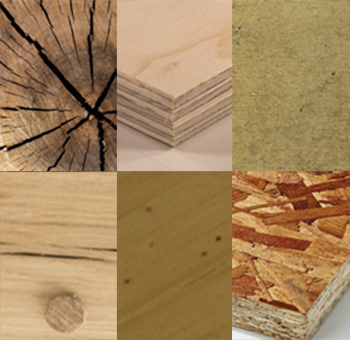

Timber in Construction Roadmap

Ambitious plans from the Government to increase the use of timber in construction.

ECA digital series unveils road to net-zero.

Retrofit and Decarbonisation framework N9 launched

Aligned with LHCPG social value strategy and the Gold Standard.

Comments

Collaboration is a fundamental aspect of quality management within any organization. It involves the coordinated efforts of individuals and teams to achieve common goals, ensure high-quality outcomes, and continuously improve processes. From a quality management perspective, collaboration plays a crucial role in enhancing efficiency, effectiveness, and overall performance. Here's how collaboration contributes to quality management:

1. **Cross-Functional Expertise:** Quality management requires input from various departments and disciplines within an organization. Collaborating across functions allows for the integration of diverse expertise, enabling a more comprehensive understanding of processes and potential improvement opportunities.

2. **Shared Knowledge and Best Practices:** Collaboration fosters the sharing of knowledge and best practices among team members. When individuals with different experiences and perspectives come together, they can identify innovative solutions, streamline processes, and implement proven methods that enhance overall quality.

3. **Problem-Solving:** Collaborative efforts are effective in addressing complex quality-related issues. Teams can collectively analyze problems, identify root causes, and develop solutions. A collaborative approach often results in more robust and sustainable solutions due to the diversity of input.

4. **Communication and Transparency:** Effective collaboration requires clear and open communication. Transparency in sharing information about quality standards, goals, and progress ensures that all team members are on the same page and aligned with the organization's quality objectives.

5. **Continuous Improvement:** Collaborative environments are conducive to continuous improvement initiatives. Team members can collectively identify areas for enhancement, implement changes, and monitor the outcomes. This iterative process supports ongoing quality enhancement.

6. **Employee Engagement:** Involving employees in collaborative quality management initiatives increases their engagement and ownership of the organization's quality goals. Employees feel valued when their input is considered, leading to increased commitment to maintaining high-quality standards.

7. **Risk Management:** Collaboration helps identify and mitigate potential risks that could impact quality. When teams work together to assess risks and develop contingency plans, the organization becomes better equipped to handle unexpected challenges.

8. **Innovation:** Collaborative environments encourage creativity and innovation. When individuals with diverse perspectives collaborate, they can generate new ideas and approaches to improve quality processes and outcomes.

9. **Quality Metrics and Measurement:** Collaborative efforts enable the establishment of meaningful quality metrics and measurements. Teams can jointly determine key performance indicators (KPIs) that accurately reflect the organization's quality goals.

10. **Change Management:** When implementing changes to improve quality, collaboration helps manage resistance to change. Involving stakeholders in the decision-making process and addressing their concerns can lead to smoother transitions.

11. **Supplier and Customer Relationships:** Collaboration extends beyond organizational boundaries to include suppliers and customers. Collaborative relationships with suppliers help ensure the quality of incoming materials, while working closely with customers allows for understanding their expectations and feedback.

12. **Training and Development:** Collaborative efforts can lead to the development of training programs that ensure all team members are knowledgeable about quality standards and procedures.

Overall, collaboration is a driving force in quality management, fostering a culture of continuous improvement, innovation, and shared responsibility for achieving high-quality outcomes. Organizations that prioritize collaboration as part of their quality management approach are better equipped to meet customer expectations, comply with industry regulations, and sustain long-term success.