Steps to Making High-Quality Cold Rolled Steel Coils

Contents |

[edit] Introduction

Cold rolled steel coils usually have a thickness ranging from 0.2 mm to 4 mm. They go through a complicated manufacturing process, involving heat treatment, cold rolling, and pickling.

[edit] Pickling

The hot rolled coils go through a pickling line consisting of hydrochloric acid solutions and scale breaker machines. These two systems remove any type of oxide film or surface scale on the rolls. Oxide films may cause surface flaws, thus reducing the overall quality of the rolls when they enter the cold rolling stage.

[edit] Cold rolling

Once the hydrochloric acid solutions and scale breaker machines remove the oxide films, the rolls go into the tandem mills one by one. The tandem mills are responsible for setting the thickness of the rolls. They can cut down the dimensions by up to 90%, depending on the requirement. Once the steel rolls pass through the tandem mills, there are no options to change their sizes.

[edit] Electrolyte cleaning

Cold rolled steel rolls contain a lot of contaminants and lubricant oil. Not cleaning them would lead to spots on the rolls. Electrolyte cleaning is essential to make sure that no roll contains even a speck of contaminant. Even a drop of oil may later look like a big spot.

[edit] Annealing or heat treatment

This is a crucial stage of producing high-quality cold rolled steel coils. In this stage, a two heat treatment method is used: continuous annealing and batch annealing. These two heat treatment methods are used simultaneously to provide high tensile strength to the rolls. The steel rolls also achieve better drawing qualities because of the multiple annealing methods.

[edit] Skin pass

The skin pass is a quality-check stage where the rolls go through a final rolling process. This rolling process can remove any sort of stretch marks or defects on the rolls. Once the rolls pass through this stage, you will see a smooth and lustrous surface. In addition to removing the stretch marks, the skin pass reduces the thickness of the coils by 1%.

Featured articles and news

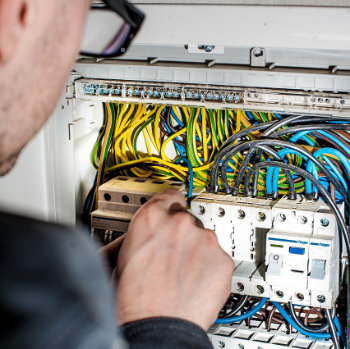

Classroom electrician courses a 'waste of money'

Say experts from the Electrical Contractors’ Association.

Wellbeing in Buildings TG 10/2025

BSRIA topic guide updates.

With brief background and WELL v2™.

From studies, to books to a new project, with founder Emma Walshaw.

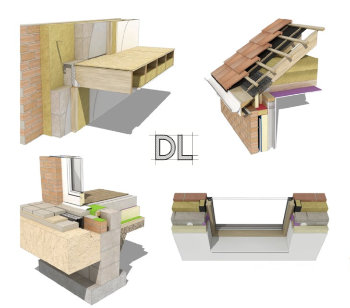

Types of drawings for building design

Still one of the most popular articles the A-Z of drawings.

Who, or What Does the Building Safety Act Apply To?

From compliance to competence in brief.

The remarkable story of a Highland architect.

Commissioning Responsibilities Framework BG 88/2025

BSRIA guidance on establishing clear roles and responsibilities for commissioning tasks.

An architectural movement to love or hate.

Don’t take British stone for granted

It won’t survive on supplying the heritage sector alone.

The Constructing Excellence Value Toolkit

Driving value-based decision making in construction.

Meet CIOB event in Northern Ireland

Inspiring the next generation of construction talent.

Reasons for using MVHR systems

6 reasons for a whole-house approach to ventilation.

Supplementary Planning Documents, a reminder

As used by the City of London to introduce a Retrofit first policy.

The what, how, why and when of deposit return schemes

Circular economy steps for plastic bottles and cans in England and Northern Ireland draws.

Join forces and share Building Safety knowledge in 2025

Why and how to contribute to the Building Safety Wiki.

Reporting on Payment Practices and Performance Regs

Approved amendment coming into effect 1 March 2025.