Mortar

Mortar is one of the oldest building materials, enabling large structures to be constructed from small, easy-to-handle components. It was used by the Romans, Greeks and Egyptians, and the oldest example may date back as far as 10,000 years in Israel (ref. Mortar Industry Association).

It is composed from a mixture of a fine aggregate (typically sand), a binder (typically cement, but sometimes lime or a combination of lime and cement) and water. This combination creates a paste that is used in masonry construction as a bedding and adhesive to bind and fill the gaps between adjacent blocks of brick, concrete or stone.

Mortar is applied as a thick paste which sets hard as it cures. It creates a tight seal between bricks and blocks to prevent air and moisture entering into the construction. It can compensate for variations in brick or block size to produce an aesthetically-pleasing and structurally-sound construction. Generally, it is structurally weaker than the blocks or bricks it bonds, creating a sacrificial layer that is more easily repaired than defects would be in the bricks or blocks themselves.

Mortar is generally very durable and has a typical lifespan of between 20-30 years, after which repairs (or repointing) can be necessary to fill cracks or gaps that may begin to appear.

Mortar may be provided in its component parts and mixed on site, or factory-mixed. The two main types of factory-produced mortar are:

- Wet ready-to-use mortar that requires no further mixing.

- Dry ready-to-use mortar which requires the addition of water.

Factory-produced mortar is made under tightly-controlled conditions and provides:

- Consistent quality, colour and strength.

- Reduced mixing and labour costs.

- Reduced wastage.

- Guaranteed specification.

- Improved site health and safety.

For the different types of mortar, see Types of mortar.

The profile of mortar joints (pointing) can be varied depending on exposure or to create a specific visual effect. The most common profiles are; flush (rag joint), bucket handle, weather struck, weather struck and cut, and recessed.

A wide range of colours are available to match or contrast with the surrounding bricks or blocks, or to match existing mortar. Pigments are specified according to BS EN 12878:2014 Pigments for the colouring of building materials based on cement and/or lime. Specifications and methods of test.

A range of admixtures can be included in mortar, such as plasticisers, bonding agents, and waterproofing. These can be specified according to BS EN 934-3:2009+A1:2012 Admixtures for concrete, mortar and grout. Admixtures for masonry mortar. Definitions, requirements, conformity and marking and labelling.

Mortar must have good workability to ensure there are no air pockets which might prevent proper bonding. Plasticisers can improve workability by entraining very small air bubbles in the mix. Alternatively, the addition of lime can improve the workability of mortar.

Where porous bricks or blocks are being laid, the mortar may dry quickly, preventing proper levelling and so preventing a good bond from being formed. This can be countered by laying shorter lengths or by limited wetting.

[edit] Related articles on Designing Buildings

- Cement.

- Cement mortar.

- Defects in brickwork.

- Defects in stonework.

- Dry hydrate lime mortar.

- Efflorescence.

- Gauged mortar.

- Hot-mixed mortars: the new lime revival.

- Hungry joints.

- Lime mortar.

- Lime putty mortar.

- Mortar analysis for specifiers.

- Rendering.

- Repointing.

- Spalling.

- Stucco.

- Technical Paper 32 – A Data Driven Approach to Understanding Historic Mortars in Scotland.

- Textile-reinforced mortars TRM.

- Types of mortar.

- Which way up should you lay a brick?

[edit] External references

- Mortar Industry Association (MIA).

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings for people to come home to... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

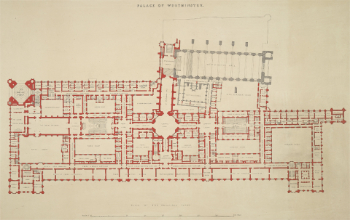

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

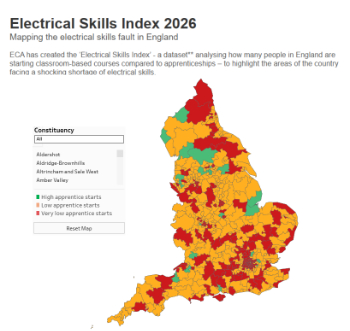

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

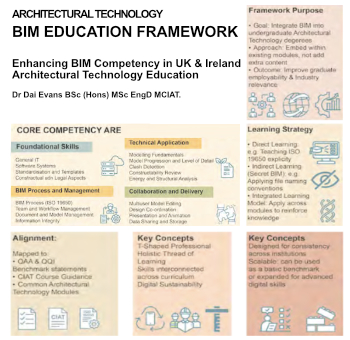

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”