Hospital isolation rooms

Contents |

[edit] Introduction

Isolation rooms for the prevention of airborne infection are an integral part of hospitals, ensuring immuno compromised patients are protected from infection and infectious patients are isolated. They are designed in accordance with the biosafety level of the pathogens they are likely to contain or isolate from.

Effective isolation rooms require careful consideration and in recent years BSRIA has assisted the Department of Health in improving their design validation practice.

[edit] New space design is helping patients’ protection

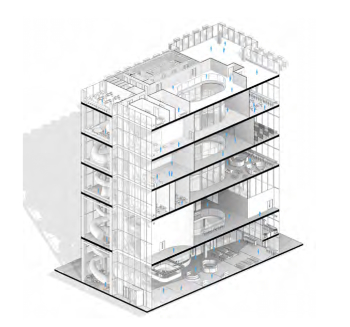

Pressure differentials isolate the rooms from the rest of the hospital. Positively pressurised rooms tend to be used to protect patients that have been immuno compromised, whereas negative isolation rooms are used to isolate an infectious patient. Air flows from a higher pressurised space into a lower pressurised space, so in positive isolation rooms, the patient is protected from infections occurring elsewhere in the hospital. In the case of negative isolation rooms, air cannot flow from the room into the hospital, therefore isolating the infection, but consideration must be given to the protection of the patient from a different infection. In recent years, new designs incorporating a Positively Pressurised Ventilated Lobby (PPVL) and neutral patient rooms have been described by the Department of Health in HBN4 (Isolation facilities for infectious patients in acute settings) and tested and validated by BSRIA.

A PPVL, set at a higher pressure than both the patient’s room and the hospital corridor, prevents air from the corridor entering the patient’s room, therefore protecting the patient, and at the same time preventing air from the room, and from a potentially infectious patient, to flow into the corridor. In addition, these rooms incorporate an “en suite” bathroom, at a negative pressure with respect to the patient’s room, ensuring all air is extracted through the “en suite” and filtered prior to release outside.

The pressure differentials in these rooms tend to be in the order of 10 Pa. Pressure differentials do not need to be as large as in other applications to ensure air flows in the desired direction. In practice, very large pressure differentials could make the doors more difficult to open and would mean higher leakage rate of potentially contaminated air in the event of poor airtightness of the room.

[edit] Good airtightness helps achieve effective isolation

Good airtightness will assist in commissioning the rooms, ensuring pressure stabilisers work properly, rooms are pressurised, and AHU are operating within the design envelope. By ensuring the structure leaks as little as possible, it is easier to achieve design pressures.

In the event of fan failure, even if it is temporary, the walls of the room constitute the first line of defence against airborne infection. Building for airtightness ensures, that in the event of fan failure, there are not-unaccounted-for flows of potentially contaminated air flowing into areas that are, in principle, risk free. E.g. in a 10 Pa pressure differential, an airtightness of 1 m³/h/m² would equate to 60 l/s of air (which is equivalent to having another door) flowing from the isolation room into other areas of the hospital, where people may not be wearing PPE. A good (low) level of airtightness is much easier to achieve if it is considered through design and the constructions stages.

[edit] BSRIA standard on Air permeability of isolation rooms (BTS3) forms part of NHS guidance HBN4

A methodology for testing the airtightness of isolation rooms has been described in BSRIA’s technical standard 'BTS 03: Air permeability of isolation rooms' and has been included in the NHS guidance to isolation rooms 'HBN4 Isolation facilities for infectious patients in acute settings'.

Nowadays, we could be talking about entire hospital wings dedicated to isolation. In this case, the PPVL and airtightness principles could be applied as well to ensure that the patients are properly isolated as well as protected.

Click here to download a copy of BSRIA's Air permeability testing of isolation facilities (BTS 3/2018) Standard.

This article was originally published on the BSRIA blog in March 2020, it was written by Dr Blanca Beato-Arribas, BSRIA Microclimate Team Leader.

--BSRIA

[edit] Related articles on Designing Buildings

- Air change rate.

- Air permeability in isolation rooms.

- Air permeability testing.

- Air permeability testing of isolation facilities.

- Air permeability.

- BSRIA articles on Designing Buildings Wiki.

- BSRIA.

- Clean indoor air for healthy living - New air filter standards.

- Coronavirus.

- Design of isolation rooms for infection control.

- Emergency healthcare architecture in Brazil.

- Indoor air quality.

Featured articles and news

The need for a National construction careers campaign

Highlighted by CIOB to cut unemployment, reduce skills gap and deliver on housing and infrastructure ambitions.

AI-Driven automation; reducing time, enhancing compliance

Sustainability; not just compliance but rethinking design, material selection, and the supply chains to support them.

Climate Resilience and Adaptation In the Built Environment

New CIOB Technical Information Sheet by Colin Booth, Professor of Smart and Sustainable Infrastructure.

Turning Enquiries into Profitable Construction Projects

Founder of Develop Coaching and author of Building Your Future; Greg Wilkes shares his insights.

IHBC Signpost: Poetry from concrete

Scotland’s fascinating historic concrete and brutalist architecture with the Engine Shed.

Demonstrating that apprenticeships work for business, people and Scotland’s economy.

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.