Thermostatic mixing valves and water safety

Whether a homeowner or land-lord or a local council, building owners have a duty of care for those living, working, or using their facilities, which is why thermostatic mixing valves (TMV) play a crucial role in all plumbing systems. It is imperative that some form of TMV be specified for every hot water system. The main benefit of a TMV is keeping water at a safe temperature, which therefore prevents scalding and helps stop the build-up of harmful Legionella bacteria. This is achieved by mixing hot and cold-water streams together to ensure a safe temperature at the outlet.

The type of TMV required for an individual application will vary greatly on what kind of building the specification is taking place in, as domestic and commercial buildings have a different requirement to buildings in the healthcare sector.

It is recommended that in domestic and commercial environments, a TMV2 approved valve is specified, and safely installed, tested and maintained to current standards. These valves are designed to reduce the risk of scalding at outlets, while minimising the potential build-up of Legionella bacteria in the pipework that is fed from the outlet side of the valve to the tap. They are typically found under sinks and basins, and never more than 2m away from the outlet they are serving. For buildings occupied by the healthcare sector, such as hospitals, a TMV3 needs to be specified, which functions the same way as a TMV2, but undergoes more rigorous testing, both at the point of installation, as well as every six months after initial sign- off. This is to ensure the safety of the end users, who are likely to be more vulnerable to both scalding and the potential harmful infection from Legionella bacteria.

Where a TMV2 can typically only work with water pressures of 5 bar or below, a TMV3 is safe to work with 10 bars of water pressure.

Water safety in buildings, published by the World Health Organization in 2011, defines thermostatic mixing valves as: ‘Tempering valves that are typically temperature-activated. Used to mix hot and cold water to achieve a predetermined outlet temperature, and that are fitted between the water heater and the point of use to control the distribution temperature. Slightly different temperature ranges are used in some countries.’

Legionnaires' Disease - Operation and Maintenance Log Book (BG 58/2015), written by Reginald Brown and Salim Deramchi, and published by BSRIA in May 2015, defines a thermostatic mixing valve as a: ‘Mixing valve in which the temperature of the water at the outlet is pre-selected and automatically controlled by the valve.’

The above article includes an extract of "Do not get your ABCs confused – all you need to know about TMVs, PRVs and the Tenant Valve" published in the AT journal, issue 144, Winter and written by Richard Bateman, Product Marketing Manager, RWC

--CIAT

[edit] Related articles on Designing Buildings

- A guide to installing thermostatic mixing valves: what, why and how.

- Domestic hot water.

- Mechanical, electrical and plumbing MEP.

- Ofwat.

- Pipework defects, ventilation and airflow rates.

- Pipework.

- Pressure independent control valves.

- Pressure-relief valve.

- Pumps and dewatering equipment.

- Radiator.

- Tap.

- Thermostatic mixing valve.

- Types of valve.

- Types of water.

- Valve.

- Water safety plan WSP

- Water.

Featured articles and news

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.

Cutting carbon, cost and risk in estate management

Lessons from Cardiff Met’s “Halve the Half” initiative.

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

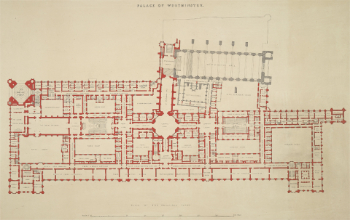

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.