Cathodic protection in church towers

Cathodic protection, the application of a small negative charge to the iron or steel, is being used increasingly to control corrosion of embedded iron within historic buildings.

|

| An anode ribbon being installed internally either side of the ring beams using rope access at St Aldhelm’s Church, Doulting. |

Corrosion of iron tie bars, ring beams and cramps is becoming an increasing problem in our heritage building stock. Although the rate of corrosion is relatively low, in the long term it results in the fracturing of stones and sometimes the loss of structural integrity. In the past architects have attempted to remove as much as possible of the original iron fittings and replace them with more corrosion-resistant materials. The policy now followed in the UK for heritage buildings is that of ‘minimum intervention’, with the intention of retaining as much of the original fabric as possible. In the 18th and 19th centuries, tie bars, ring beams and cramps were usually made from wrought iron, which is susceptible to corrosion when exposed to air and moisture. The situation may be exacerbated if sedimentary stones, such as Portland or Bath, are used in the construction. These sometimes contain chloride and/or sulphate salts, which result in the depassivation of the iron surface and an acceleration of corrosion. Corrosion rates are also significantly higher where iron is in direct contact with damp stone as compared to exposure to air.

For major construction work during this period the wrought iron was sometimes surrounded by lead. Lead corrodes at a very slow rate in this environment. If it completely surrounds the fitting, the iron should be protected from corrosion. However, this is rarely the case for heritage buildings, and especially for church towers, where the melting of lead on wooden scaffolding during construction would have been minimised. For unprotected iron the corrosion results in expansion forces, which eventually exert such pressure on the stone that it cracks or spalls. The volume ratio between iron and rust can be as high as 1:7.

Ring beams were originally incorporated into towers to resist the masonry buckling outwards and to strengthen the walls to resist wind loading. Normally they are embedded within the external masonry to maximise support to the tower, but sometimes they are embedded within the internal masonry if the thickness of the wall changes due to the presence of windows or louvres.

The conventional remedy has usually involved surgery to remove the iron fittings and cramps. They may sometimes be replaced with non-corroding phosphor bronze or stainless steel, or even left without replacement, prior to repair to the stonework. Conventional treatments can sometimes be highly invasive, involving large-scale opening up to expose and treat affected components, or even demolition to replace the iron. Cathodic protection offers a non-intrusive, alternative approach to the treatment of rusting iron embedded in masonry and stone.

In 1824 Sir Humphrey Davy presented a series of papers to the Royal Society describing how cathodic protection could be used to prevent the corrosion of copper sheathing in the wooden hulls of British naval vessels. Since then it has been applied to many other areas, including marine applications, and for the preservation of buried underground structures such as pipelines and tanks. Over the past 30 years the technology has been applied to concrete to protect steel reinforcement from corrosion. Over the past 20 years it has also been applied to iron and steel embedded in brick, masonry and stone in heritage buildings.

Corrosion is an electrochemical reaction involving both anodic and cathodic sites on an iron or steel surface. At the anodic site corrosion occurs as iron gives up electrons and forms soluble iron salts. At the adjacent cathodic site the electrons released by the corrosion process combine with water and oxygen to form hydroxyl ions. Both these partial reactions have to proceed at the same rate, otherwise a build-up of electrons would occur, suppressing the anodic process. In cathodic protection systems the metal to be protected is supplied with electrons from an external source. The entire metal surface is thereby forced to act as a cathode, so controlling further corrosion. When cathodic protection is used to protect embedded iron, small DC currents are supplied to the metal via the building material. This constant stream of electrons (which move in the opposite direction to the conventional current flow) satisfies the cathodic reaction and suppresses the anodic (corrosion) reaction.

Cathodic protection may be achieved by two somewhat different techniques: sacrificial anode cathodic protection and impressed current cathodic protection.

Sacrificial anode cathodic protection (SACP) systems use sacrificial anodes (made of zinc, aluminium, magnesium or alloys of these) which corrode preferentially to the metalwork. These are placed close to the corroding metalwork and are electrically connected to it. As the sacrificial anode corrodes it generates a current that passes through the building material to provide protection to the embedded metalwork. The current is conducted ionically through the building material by means of pore water contained within it.

The main restriction in using a SACP system is that these anode materials have only a small natural ‘driving’ potential (that is, the force which drives the electrons through the cathodic protection circuit, typically less than 1.5V), when coupled to the embedded metalwork. This is further reduced by having to overcome the ionic resistance encountered in the building material. For this reason the distance between the sacrificial anode and the embedded metalwork is normally restricted to a few metres. Another restriction is that the anodes are consumed and will need replacing. These anodes (normally buried in the ground) are capable of protecting small metal components, such as embedded iron cramps and small tie rods, set into floors or at low level in walls of buildings.

Impressed current cathodic protection (ICCP) systems require an external power supply, normally mains-powered transformer rectifiers, to provide the DC current to the iron or steel to be protected. These systems use non-corroding anodes, located close to the metalwork, to provide part of the current pathway. ICCP systems are generally more complex than the SACP systems but, with their much higher driving voltage, they are suitable for providing current to much larger areas of embedded iron, such as ring beams, or where the stone or masonry has an inherently higher electrical resistance.

As the ICCP system forces the metal to become cathodic, and therefore protected, the other side of the cathodic protection circuit (the current emitter) becomes anodic and therefore more ‘corrosive’. Materials for these current emitters (or ‘anodes’) therefore have to be highly resistant to corrosion. A variety of commercial anodes are available for use with ICCP systems. For extended use, embedded titanium anodes are normally used.

Titanium on its own is unsuitable as it readily oxidises in air, especially when acting as an anode. It builds up an electrically resistive barrier. A conductive ceramic mixed metal oxide (MMO) coating is therefore applied to titanium substrates to give a low resistance layer to emit the current. The MMO-coated anodes (typically containing mixtures of iridium, ruthenium, titanium and tantalum oxides) are now available as mesh, ribbon or wire. These are suitable for supplying high currents (up to 110mA/m2) and have a reported lifetime in excess of 75 years.

The design of a CP system should also take into account many other factors, including the surface area of iron to be protected; the resistivity of the masonry or stonework; the distance and uniformity of the anodes to the embedded metalwork; the service lifetime of the cathodic protection system; and the aesthetics of the building.

Iron tie bars are commonly encountered in the masonry of church towers. They are frequently bolted or riveted together to form ring beams to provide integrity to the structure. If the bars are already mechanically connected together, only a single (duplex) electrical connection is required to allow it to become the ‘negative’ side of the cathodic protection circuit.

The ‘positive’ side of the circuit is formed by the anode ribbon, which should be installed equidistantly above and below the tie bars or ring beam. If the ring beams are fitted externally, the anode ribbon should also be fitted in the external joints. This has the added benefit that the external faces of the stones normally have higher moisture contents, as compared to the inner faces, and their electrical resistance will therefore be lower, requiring less driving potential. Sometimes the ring beams are mounted internally, which may require internal scaffolding, or possibly working with rope access specialists, to install the system.

Reference electrodes should also be embedded close to the protected iron surfaces to monitor the performance and to enable adjustment of the cathodic protection system.

Wrought-iron cramps are commonly found between stones in many church towers. Corrosion of the cramps results in expansion and cracking of the stones. If the situation is left unchecked, rainwater may have direct access to the iron cramps, increasing the rate of corrosion.

Many of the corroded iron cramps can be removed when the wounded stone is repaired and/or stainless steel cramps are inserted. The remaining cramps which have not yet damaged the stones will require ‘daisy-chaining’ to form a single ‘negative’ side for the CP circuit.

The transformer rectifier and other electronics may be expected to have a lifetime of between 20 to 40 years, after which they can readily be replaced. The external wiring may also need replacement after 40 to 60 years. However, the embedded anodes and internal wiring within the masonry and stonework are not easily replaced and should therefore be selected to give a maximum service life.

MMO-coated titanium anodes are reported to have lifetimes of more than 75 years. Any embedded wiring on the anodic (positive) side of the circuit should use titanium wire. The DC negative wiring, which connects to the iron or steel, is effectively under cathodic protection and so should not suffer deterioration. Embedded reference electrodes, used to monitor the performance of the CP system, have a reported life of around 20 years, although some have been known to fail within five years. Surface-mounted reference electrodes may be substituted in their place. These may be fixed to the outer masonry or stonework to assess the performance of the system, and then removed.

The first cathodic protection system installed in the UK on a heritage structure was carried out by English Heritage to protect embedded iron cramps on the Inigo Jones gateway at Chiswick House in 1996. The transformer rectifier failed within the first few years and the CP system was converted to a modified SACP system. This structure, which is still monitored on an annual basis, shows no corrosion or iron staining of the masonry surrounding the cramps.

A second cathodic protection SACP system was installed in 1999 to protect rusting cramps in the stone facade of four Grade II listed almshouses in Whitchurch. The stones formed an interlocking frontage with iron cramps fitted between adjacent blocks. Water had permeated into the stonework joints and had allowed the iron cramps to corrode. The expanding corrosion products had introduced internal stresses that had resulted in cracking and spalling to some of the stones.

Damaged stones, located on the outer edges of the facade, were replaced with new stones fitted with stainless-steel cramps. For the remaining, as yet undamaged stones, a SACP system was installed to control further corrosion of the iron cramps. Magnesium anodes were buried in the pavement in front of the cottages. These were connected directly through to the cramps in a ring circuit.

The cottages were inspected in 2009, 10 years after installation. A visual assessment showed no spalling or iron staining where CP had protected the cramps. However, a stray cramp within the chimney, which had not been detected in 1999 and which had been omitted from the SACP system, had continued to corrode and had blown the stone.

One of the principal advantages of cathodic protection is that it provides corrosion control without changing the immediate physical environment. There may still be now, or in the future, damp stone, masonry or concrete adjacent to the metal, which would previously have allowed corrosion to continue. Cathodic protection provides the electrochemical conditions to control this corrosion process.

In many instances, the removal and replacement of iron tie bars and ring beams is likely to be both disruptive and expensive. Installation of a CP system is significantly easier, requiring opening up of the joints either side of the iron, insertion of anode ribbon in the joints and re-pointing up afterwards. In a church tower, for example, the cost may typically be between £2,000 and £8,000 (2015 prices).

Further reading

- Morgan, J (1993) Cathodic Protection (second edition), National Association of Corrosion Engineers

- Blackney, K and Martin, W (1998) The Application of Cathodic Protection to Historic Buildings, English Heritage Research Transactions

- Gibbs, P (2000) Corrosion of Masonry Clad Steel Framed Buildings, Historic Scotland, Technical Conservation Research and Education Division, Technical Advice Note 20

- Farrell, D, Davies, K and McCaig, I (2001) ‘Cathodic Protection of Iron and Steel: recent developments to heritage buildings’, The Building Conservation Directory Farrell, D and Davies, K (2005) ‘Cathodic Protection of Iron and Steel in Heritage Buildings in the United Kingdom’, Association for Preservation Technology Bulletin, Vol XXXVI

This article originally appeared in the Institute of Historic Building Conservation’s (IHBC’s) Context 139, published in June 2015. It was written by David Farrell, managing director of Rowan Technologies..

--Institute of Historic Building Conservation

Related articles on Designing Buildings

IHBC NewsBlog

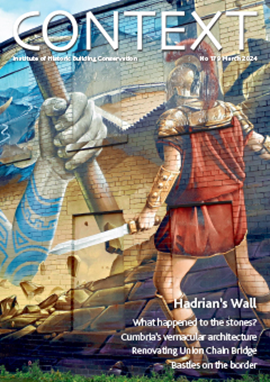

IHBC Membership Journal Context - Latest Issue on 'Hadrian's Wall' Published

The issue includes takes on the wall 'end-to-end' including 'the man who saved it'.

Heritage Building Retrofit Toolkit developed by City of London and Purcell

The toolkit is designed to provide clear and actionable guidance for owners, occupiers and caretakers of historic and listed buildings.

70 countries sign Declaration de Chaillot at Buildings & Climate Global Forum

The declaration is a foundational document enabling progress towards a ‘rapid, fair, and effective transition of the buildings sector’

Bookings open for IHBC Annual School 12-15 June 2024

Theme: Place and Building Care - Finance, Policy and People in Conservation Practice

Rare Sliding Canal Bridge in the UK gets a Major Update

A moveable rail bridge over the Stainforth and Keadby Canal in the Midlands in England has been completely overhauled.

'Restoration and Renewal: Developing the strategic case' Published

The House of Commons Library has published the research briefing, outlining the different options for the Palace of Westminster.

Brum’s Broad Street skyscraper plans approved with unusual rule for residents

A report by a council officer says that the development would provide for a mix of accommodation in a ‘high quality, secure environment...

English Housing Survey 2022 to 2023

Initial findings from the English Housing Survey 2022 to 2023 have been published.

Audit Wales research report: Sustainable development?

A new report from Audit Wales examines how Welsh Councils are supporting repurposing and regeneration of vacant properties and brownfield sites.

New Guidance Launched on ‘Understanding Special Historic Interest in Listing’

Historic England (HE) has published this guidance to help people better understand special historic interest, one of the two main criteria used to decide whether a building can be listed or not.