Code of Practice for Ironwork Systems Installation and Refurbishment

The new Code of Practice for Ironwork Systems Installation and Refurbishment was introduced in May 2017.

Published by the Road Surface Treatments Association (RSTA), and peer-reviewed and endorsed by, amongst others, Highways England and Adept, the Code is designed to “provide practical guidance on avoiding early life failure and to achieve a high quality installation and a high quality repair.” It was developed by the industry for the industry and is intended to promote the best standards of design, materials and installation methods.

Currently, the service life expectation and specification guidance for the installation and refurbishment of ironworks varies greatly across the UK, and existing guidance often covers products and components in isolation. Through the introduction of an industry-wide code of practice, minimum standards of product quality and practice can be established, giving a greater level of assurance to clients, contractors and users.

Under typical conditions, the cost of materials and components used in the installation of ironworks equates to approximately 20% of the overall project [1] - it is traffic management, installation and reinstatement of surfacing that attracts the largest costs. Failure of ironworks installations due to poor workmanship results in greatly increased costs. It makes sense therefore to adopt the practice of ‘right first time’. The new Code of Practice will help to reinforce this message and lead to better and longer-lasting ironwork installations.

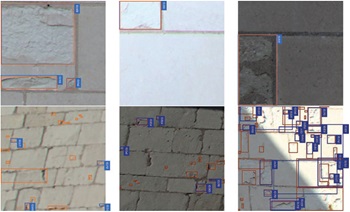

The Code of Practice is a comprehensive, easy-to-follow guide which is relevant to all designers, manufacturers and installers in the road improvements industry. It includes a detailed description of common indicators of failing installations; recommendations for ironwork specification and selection; and a useful checklist, encouraging best practice prior to, during and after works have been completed.

Howard Robinson, Chief Executive, Road Surface Treatments Association said:

"As the focal point for the road maintenance sector, the RSTA and its members are well-placed to provide overall industry best practice guidance. This new code is part of a growing knowledge centre for successful road work and maintenance. To ensure its validity the Code took three years to develop and I would like to thank those members involved for their valued input and feedback.

"Since its launch in May, the Code has been well-received by the industry. This Code fully explains what is expected from the client and from the contractor. It is all about using best practice to get it right first time".

Wayne Perrin, Business Development Manager for IKO PLC, a member of the RSTA, has been actively involved in the development of the new Code of Practice: “The ‘right first time’ approach put forward will lead to better and longer-lasting ironwork installations.”

For further information, visit www.rsta-uk.org.

References

- [1] RSTA. (May 2017). Code of Practice for Ironwork Systems Installation and Refurbishment. p. 5

[edit] Related articles on Designing Buildings Wiki

- Bituminous mixing and laying plant.

- Britain's historic paving.

- Conservation of Architectural Ironwork.

- Highway drainage.

- Highway infrastructure and local authorities.

- Highways England.

- Highways.

- Ironwork.

- Manual of Contract Documents for Highway Works.

- Overview of the road development process.

- Pavement.

- Road construction.

- Road joints.

- Runway construction.

- Transport design and health.

- Types of road and street.

Featured articles and news

CIOB photographic competition final images revealed

Art of Building produces stunning images for another year.

Major overhaul of planning committees proposed by government

Planning decisions set to be fast-tracked to tackle the housing crisis.

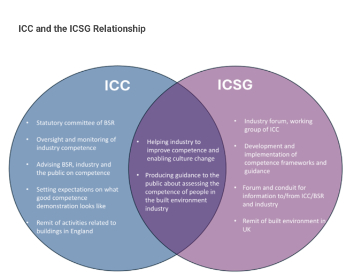

Strategic restructure to transform industry competence

EBSSA becomes part of a new industry competence structure.

Industry Competence Steering Group restructure

ICSG transitions to the Industry Competence Committee (ICC) under the Building Safety Regulator (BSR).

Principal Contractor Competency Certification Scheme

CIOB PCCCS competence framework for Principal Contractors.

The CIAT Principal Designer register

Issues explained via a series of FAQs.

Conservation in the age of the fourth (digital) industrial revolution.

Shaping the future of heritage

Embracing the evolution of economic thinking.

Ministers to unleash biggest building boom in half a century

50 major infrastructure projects, 5 billion for housing and 1.5 million homes.

RIBA Principal Designer Practice Note published

With key descriptions, best practice examples and FAQs, with supporting template resources.

Electrical businesses brace for project delays in 2025

BEB survey reveals over half worried about impact of delays.

Accelerating the remediation of buildings with unsafe cladding in England

The government publishes its Remediation Acceleration Plan.

Airtightness in raised access plenum floors

New testing guidance from BSRIA out now.

Picking up the hard hat on site or not

Common factors preventing workers using head protection and how to solve them.

Building trust with customers through endorsed trades

Commitment to quality demonstrated through government endorsed scheme.

New guidance for preparing structural submissions for Gateways 2 and 3

Published by the The Institution of Structural Engineers.

CIOB launches global mental health survey

To address the silent mental health crisis in construction.

Key takeaways from the BSRIA Briefing 2024

Not just waiting for Net Zero, but driving it.